Mcr WIP type multi-blade fire dampers

6/17

MERCOR SA –

the Company reserves the right to make modifications and changes.

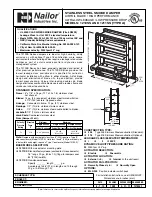

6.INSTALLATION OF THE FIRE DAMPER

NOTICE

During the installation of a fire damper and while conducting finishing work, you should allow for

the possibility of later access to the fire damper and removal of the release and control

mechanism in order to carry out possible service work and technical inspections.

The mcr WIP fire dampers may be installed in the following space dividing elements (walls or structural floors):

masonry/concrete walls with a thickness of 120 mm brickwork

walls or concrete masonry unit walls with a thickness of 120 mm

walls made of boards with a thickness of 120 mm

structural floors with a thickness of 150 mm

Additionally, fire dampers may be installed:

outside walls

in larger fire damper systems/assemblies (multi fire damper sets)

The mcr WIP type fire dampers may also be installed in space dividing elements in buildings that have a lower fire-

resistance rating. In such cases, fire dampers will have a fire-resistance rating equal to that of a space dividing

element, with the condition of smoke leakage rating being satisfied. When installing a fire damper in a given type of

wall which is thinner than required, its thickness should be increased along the perimeter of the fire damper, e.g. by

installing an additional board or other building element.

6.1. PRE-INSTALLATION INSPECTION

Each fire damper is inspected by the manufacturer before packing and transport. Once the product has been

unpacked at the destination, visual inspection should be conducted to check for possible deformations of the

housing or fire damper transport damage.

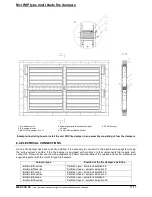

6.2. INSTALLATION OPENING

The minimum size of an installation opening necessary for correct installation of the mcr WIP type fire damper is:

Bo = (A + Bz + 80) [mm]

Ho = (H + 180) [mm]

BF

BLF

BFL

BFN

BE

BLE

KW1

EXBF

C1 [mm]

385

335

335

385

385

335

335

460

A [mm]

125

125

125

125

125

125

165

175

Mixture