85-03-01058-O

FV33i Gen 3

Page

53

4.6

LEVELING BOLTS

4.6.1

Leveling Bolts Definition

Four leveling bolts are included in the manual package. The leveling bolts allow for a ¼” minimum to 1” maximum leveling ability.

Leveling bolts are designed to adjust for uneven fireplace floors and yield plumb Insert Body. Use the leveling bolts only if the

fireplace floor is more than ¼” out of level from one side to another or from front to back. If the fireplace floor is less than ¼” out

of level, use metal sheet shims in various thickness and build up to needed leveling thicknesses at various points around the

appliance.

The leveling bolts supplied are designed specifically for application with this product. only use leveling bolts supplied by Mendota

and for leveling purposes only. Never use leveling bolts for purposes of lifting unit up to make up for ash lip heights or other

lifting or raising needs. Such use can cause extreme thermal expansion of firebox floor and can result in oil canning noise or

louder thermal expansion and constriction banging noise.

SUCH NOISE PROBLEMS ARE NOT COVERED UNDER MENDOTA

WARRANTY

Note: When lifting this Insert more than 1”, other support blocks will be required. For all applications when

you raise the unit more than 1”, reline the entire firebox floor with refractory bricks to build up a full level

floor for the Insert to sit on. Do not use individual support block only under the four corners of this unit.

WARNING: Failure to position the parts in accordance with these diagrams or failure to use only parts

specifically approved with this appliance may result in property damage or personal injury. Never use other

after-market leveling bolts. Doing so can lead to vibration noise problems or damage to internal

components.DO NOT USE LONGER BOLTS TO LIFT INSERT UPWARD. THIS CAN CAUSE OTHER SIDE EFFECTS LIKE

HEAT EXPANSION/CONTRACTION NOISES. To lift Insert up, use Firebricks and mortar or a metal box designed

specifically for this purpose.

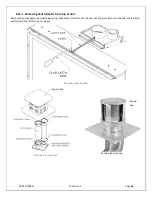

4.6.2

Leveling Bolts Installation

Perform this step after you have measured the firebox floor for level surface characteristics. Tip the Insert body on its back on

the wooden pallet. Thread one leveling bolt into each leveling bolt receiving fastener. Thread the bolt in as far as necessary to

achieve the leveling effect desired.

Leveling Bolts Installation