39

HYDRAULIC HOSES

The condition of all hoses should be carefully checked during routine service of the machine.

Hoses that have been chafed or damaged on their outer casing should be securely wrapped

with waterproof adhesive tape to stop the metal braid from rusting. Hoses that have suffered

damage to the metal braid should be changed at the earliest opportunity.

Hose replacement

a)

Replace one hose at a time to avoid the risk of wrong connections.

b)

When the hose is screwed to an additional fitting or union, use a second spanner on the

union to avoid breaking both seals.

c)

Do not use jointing compound on the threads.

d)

Avoid twisting the hose. Adjust the hose line to ensure freedom from rubbing or trapping

before tightening hose end connections.

Before changing hoses study the installation these are carefully calculated to prevent hose

damage during operation. Always replace hoses in exactly the same manner. This is

especially important for the flail hoses where they must be crossed, upper to lower, at the

dipper and head pivots. The 90-degree elbows at the head bracket must point directly across

the pivot and the hoses must have no slack at this point.

Two hose clips are provided at either end of the large bore suction and return hoses - these

should be positioned so that their worm drive barrels are opposed at 180° to reduce the

possibility of air entering the system.

Hose warranty

Warranty is limited to replacement of hoses that have failed due to faulty materials or

manufacture. Warranty will not be considered on hoses that have suffered damage by

abrasion, cuts or being pinched or trapped while in work. Neither will a claim be considered

where a hose end has been damaged by a blow or where overtightening has damaged the

threads or unions.

Gearbox

The gearbox is rigidly bolted on to the main frame and has a filler plug. Oil level is correct

when level with the filler plug aperture. The gearbox oil (SAE80/ISO100) should be changed

every year or at 600-hour intervals -

whichever occurs first.

The capacity of the gearbox is 0.5 Litres.

Summary of Contents for PA 48

Page 1: ...PA 48 HEDGE GRASS CUTTER Operator Manual Publication 469 December 2004 Part No 41570 69...

Page 2: ......

Page 4: ......

Page 12: ...3...

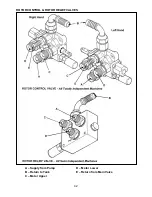

Page 32: ...ELECTRIC MONOLEVER CONTROLS PROPORTIONAL ELECTRIC CONTROLS 23...

Page 41: ...ROLLER POSITION 32...

Page 42: ...HEDGE CUTTING SEQUENCE 33...