38

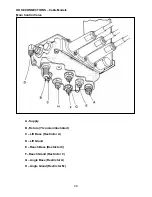

FLAIL HEAD

Frequently inspect the rotor assembly for damaged or missing flails. Bolts and nuts securing

the flails to the rotor should be regularly checked and kept tight. The correct torque setting

for these locknuts is 135 Nm (100 Ibf/ft.). Use only the correct flail bolt and locking nut.

Check the flail pivot bushes for possible damage or wear -

they do not require oil.

Do not attempt to run the rotor with flails missing. Im-balance will cause severe vibration and

can rapidly damage the rotor shaft bearings. As an emergency measure if a flail is broken off

or lost, remove another on the opposite side of the rotor to retain balance. Always replace

flails in opposite pairs and never match up a new flail with a re-sharpened one, which will of

course be lighter.

Blunt flails absorb a lot of power and leave an untidy finish to the work. They should be

sharpened on a grindstone or with a portable grinder periodically.

WARNING

Wear protective gear when sharpening flails.

Ensure that the bearing housings and hydraulic mounting nuts and bolts are kept tight. They

should be checked during servicing.

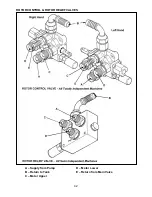

CABLES

The cables operate on a push/pull system with the spool centering springs always returning

the spool to the neutral position when the handle is released.

Care should be taken during installation and operation to ensure that the cables are not

trapped or kinked. Any abrasion or damage to the outer casing should be sealed with plastic

insulation tape to avoid moisture penetrating.

No routine adjustments of the cables are necessary, as they do not stretch. The threaded

collar is correctly adjusted when the lever is in a vertical position in its housing allowing an

equal amount of travel in either direction.

CAUTION

On no account should any attempt be made to lubricate the cables,

which are assembled with a special lubricant during manufacture.

NOTE

Take care to ascertain the correct cable connections on both the

control unit and the valve in the event of cable replacement.

Summary of Contents for PA 48

Page 1: ...PA 48 HEDGE GRASS CUTTER Operator Manual Publication 469 December 2004 Part No 41570 69...

Page 2: ......

Page 4: ......

Page 12: ...3...

Page 32: ...ELECTRIC MONOLEVER CONTROLS PROPORTIONAL ELECTRIC CONTROLS 23...

Page 41: ...ROLLER POSITION 32...

Page 42: ...HEDGE CUTTING SEQUENCE 33...