- 6 -

MAINTENANCE

WARNING

Always exercise the stopping procedure before

servicing or lubricating the unit.

After servicing the unit, replace and fasten all

guards, shields, and covers to their original

positions before resuming operation.

CAUTION

Always verify fluid levels and check for leaks after

changing fluids.

Do not drain oil onto ground, into open streams,

or down sewage drains.

Maintenance Schedule

1.

Check all hardware after the first 5 hours of use, then follow the maintenance schedule.

Ergo-Tamp Oil

The MBW Ergo-Tamp requires an inline oil supply to

function. Use of the tamper without an inline oiler will

damage the internal surfaces. A suitable oiler can be

purchased through MBW, Part #12248.

In event the tamper will be stored, pour several drops of oil

into the line to prevent corrosion.

Suppressor Grease

The MBW Ergo-Tamp requires maintenance of the

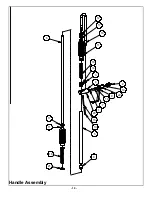

suppressor shaft (#5), Refer to Refer to Handle Assembly,

page 10. Grease shaft whenever excess hand arm vibration

is noticed. To complete maintenance perform the following

steps.

1.

Remove bottom zip tie (#17) from top bellow (#11)

and top zip tie (#17) from bottom bellow (#11).

2.

Lift bellows (#11) and apply several ounces of grease

into inner shaft suppressor (#6).

3.

Reposition the bellows (#11) and secure with new zip

ties (#17).

SYSTEM

MAINTENANCE

DAILY

EVERY 50

HOURS

EVERY 250

HOURS

YEARLY

Hardware

Check and tighten as needed

1

X

X

Suppressor

Grease suppressor shaft

X

X

Summary of Contents for ERGO-TAMP

Page 13: ...10 Handle Assembly...

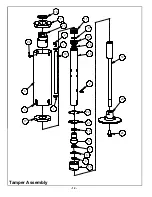

Page 15: ...12 Tamper Assembly...