- 8 -

8.

With body (#10) out of outer shroud (#6), remove

retaining ring (#19) from cap (#13) and then slide

upper shroud cover off (#7).

9.

Loosen hose camps (#1) from air hose (#18) and

then remove air hose from elbows (#2).

10. Using a metal rod placed through holes in the Tamper

body (#10) unscrew cap (#13).

11. Separate valve upper (#11), lower (#12), o-ring (#16),

and valve disc (#9) from cap (#13) (Note: Inspect

components for wear and replace if necessary).

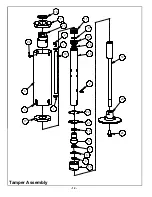

Tamper Assembly

Refer to Tamper Assembly, page 12.

1.

Place new o-ring (#16) on to lower valve (#12).

2.

Assemble upper valve (#12) lower valve (#13), and

valve disc (#9), then insert into cap (#13). (Note:

Make sure valve disc (#9) stays seated).

3.

Using medium-strength thread locking compound,

along with a metal rod placed through holes in

Tamper body (#10), screw cap (#13) over valve

assembly onto body (#10).

4.

Install air hose (#18) onto hose elbow (#2) and

secure using hose camps (#1).

5.

Using retaining ring (#19) secure upper shroud cover

(#7) to Tamper cap (#13).

6.

Slide outer shroud cover (#6) up from bottom and

connect to upper shroud cover (#7). Secure with four

screws (#20).

7.

Feed lower shroud (#17) into shroud cover (#6) and

secure with four screws (#20).

8.

Place new o-ring (#16) onto bushing support (#8) and

seal set (#4) into bushing support (#8) (Note:

Position seal set as shown below).

9.

Install new shaft wiper (#3) and shim (#5) into bottom

cap (#15).

10. Lubricate head of shaft assembly (#14) with air tool

oil and slide into body (#10)

11. Position retaining ring (#22) and locking ring (#21)

over bottom of tamper body.

12. Using air tool oil on bushing support (#8) feed support

into Tamper body (#10) and hand tighten bottom cap

(#15).

13. Secure bottom cap (#15) into position with locking

ring and retaining ring. (Note: Check ease of shaft

(#14) movement. If bottom cap (#17) is to tight shaft

movement will be difficult).

14. Using medium-strength thread locking compound on

bolt (#24) secure foot (#23) to shaft (#14). Torque to

80 ft lb. NOTE: To ensure proper tightening of

ergotamp shoe, retorque after first 15 minutes or

operation.

Handle Replacement Cycles and Tolerances

Tamper Replacement Cycles and Tolerances

6($/6(732,17

72:$5'6)227

/$5*(676($/

/2&$7('21%27720

Bushings

When bearing material has significant wear

Seal and Wiper

When air leakage occurs

Springs

When significant wear is noticed

Tube

When inside of tube becomes scoured or galled

Shaft

When shaft become bent or surface becomes scratched

Shaft

If shaft is bent it needs to be replaced

Summary of Contents for ERGO-TAMP

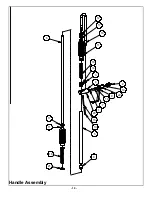

Page 13: ...10 Handle Assembly...

Page 15: ...12 Tamper Assembly...