Installation and Operational Instructions for

EAS

®

-Compact

®

overload clutch Type 49_._ _4._

Sizes 01 to 3

(B.4.14.1.EN)

13/11/2017 GC/NU/GH/SU

Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Tel.: +49 8341 804-0, Fax: +49 8341 804-421

Page 14 of 19

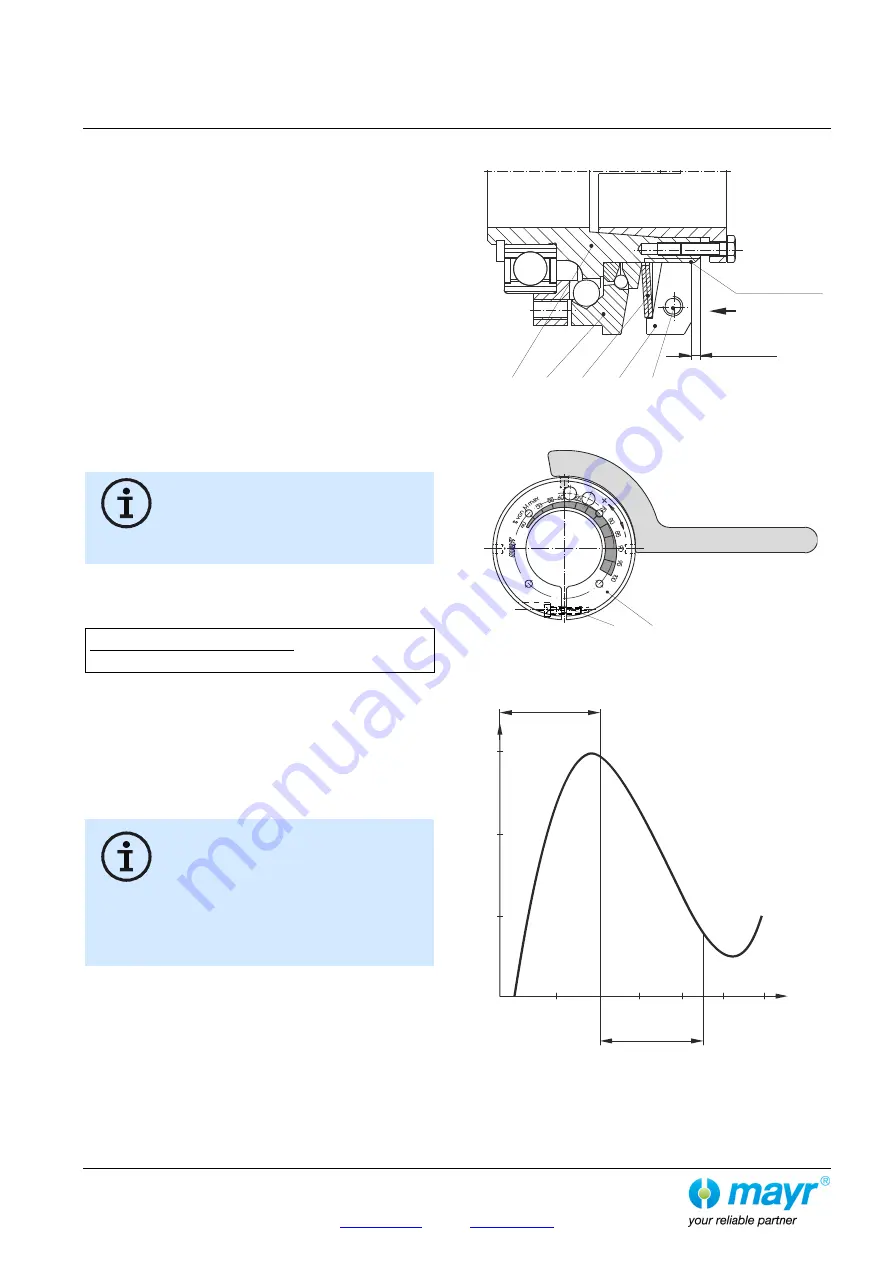

Torque Adjustment

In order to guarantee low-wear clutch operation, it is essential

that the clutch torque is set to a sufficiently high service factor

(overload torque to operating torque).

Our experience has shown that an

adjustment factor of

1.5 to 3

gives good results.

On very high load alternations, high accelerations and irregular

operation, please set the adjustment factor higher.

Torque adjustment is carried out by turning the adjusting nut (4).

The installed cup springs (9) are operated in the negative range

of the characteristic curve (see Fig. 12); this means that a

stronger pre-tensioning of the cup spring results in a decrease of

the spring force.

The torque is set manufacturer-side according to the customer's

request.

If no particular torque adjustment is requested customer-side,

the clutch will always be

pre-set

and

marked

(calibrated)

manufacturer-side to approx. 70 % of the maximum torque.

It is possible to check the

"Spring operation in the operating

range"

(Fig. 12) using the dimension "a" (distance from the

adjusting nut (4) facing side to the hub (1) facing side, as shown

in Fig. 10).

Please see Table 3 for the respective values.

Turning the adjusting nut (4) clockwise causes

a reduction in torque.

Turning it anti-clockwise causes an increase in

torque.

You should be facing the adjusting nut (4) as

shown in Fig. 10 and Fig. 11.

Changing the Torque

a) Please convert the required torque using the formula below

into percent of the maximum adjustment value (see Table 3).

Required torque adjustment

x 100 = Adjustment in %

max. adjustment value

b) Loosen the locking screw (5) in the adjusting nut (4).

c) Turn the adjusting nut (4) using the engraved adjustment

scale (Fig. 11) clockwise or anti-clockwise using a hook or a

face wrench until the required torque is reached.

d) The required torque results from the marking overlap on the

hub (1) and the percent value on the adjusting nut (Item 4 /

Figs. 10 and 11).

e) Re-tighten the locking screw (5)

(please observe the tightening torque acc. Table 5).

Adjusting the adjusting nut (4) or distorting the

cup spring (9) outside of the cup spring

characteristic curve (see Fig. 12) stops the clutch

functioning.

The inspection dimension “a” (see Table 3) can

show deviations due to construction tolerances or to clutch

wear. After de-installing the clutch

(e.g. due to cup spring replacement or changes to the cup

spring layering), the clutch must be re-adjusted and calibrated

using dimension "a" (see Table 3 and Fig. 9).

Fig. 10

Fig. 11

Fig. 12

5

9

3

1

4

5

4

Marking

Facing direction

Dim. “a”

Hook wrench

Move to

operating range

Graph of spring

characteristic

curve

Operating

range

Spring path S

F

orc

e F