27

ENG

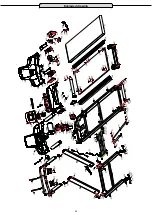

Parts List

Part

Description

Type

QTY

1

Baseframe

1

2

Platformframe

1

3

Inclineframe

1

4

Uprightpost(left)

1

5

Ezfit linkingparts

1

6

Motorbase frame

1

7

Consoleframe

1

8

Uprightpost(right)

1

9

Hex half threadscrew

M12×Φ14×35×19

2

10

AllenC.K.S.half threadscrew

M10×65×20

1

11

AllenC.K.S.half threadscrew

M10×35×20

3

12

Philipsself-tappingscrew

ST4×15

12

13

AllenC.K.S.half threadscrew

M8×50×20

3

14

AllenC.K.S.half threadscrew

M8×30×20

1

15

AllenC.K.S.full threadscrew

M8*15

10

16

Allensocketfull threadscrew

M8×75

3

17

Hex full threadscrew

M8×75e

1

18

Allensocketfull threadscrew

M8×15

2

19

Bolt welding

M8×65

1

20

PhilipsC.K.S.self-tappingscrew

ST3×15

4

21

Philipsfull threadscrew

M6×30×Φ16

6

22

PhilipsC.K.S.screw

M5×10

6

23

PhilipsC.K.S.screw

M4×10

9

24

PhilipsC.K.S.self-tappingscrew

ST4×16

29

25

PhilipsC.K.S.self-tappingscrew

ST4×12

12

26

PhilipsC.K.S.self-tappingscrew

ST4x16

28

27

Flat washer

Φ10

3

28

Flat washer

Φ8

16

29

Lockwasher

Φ5

4

30

Hex self-lockingnut

M10

3

31

Hex self-lockingnut

M8

6

32

Powdermetallurgyset

Φ17×Φ10×14

2

33

Spring

1

34

Siderail

2

35

End cap

1

36

Bottle

1

37

Consolehousing

1

38

IPAD pallets

1

39

Screenboard

1

40

Safetykey

1

49

Siderail guider

10

50

Wheel

4

51

AllenC.K.S.half threadscrew

M8×40×20

2

52

Springwasher

Φ5

3

53

Springwasher

Φ8

2

54

Hex full threadscrew

M8×20

2

55

AllenC.K.S.half threadscrew

M8×55×20

4

56

Foamgrip

2

57

Feetpad

4

58

Powercord buckle

1

59

Springwasher

Φ5

4

60

Tube plug

1

61

Switch

1

62

Fuse (withwire)

1

63

Controller

1

Part

Description

Type

QTY

64

Powercord

1

65

Filter

1

66

Speedsensor

1

67

Fan

1

68

Motor

1

69

Inclinemotor

1

70

Runningdeck

1

71

Frontroller

1

72

Rearroller

1

73

Cylinder

1

74

Motorbelt

1

75

Runningbelt

1

76

Magnetic ring

Φ36XΦ22X15

2

77

Uprightpost wire

1

78

Controllerwire

1

79

Consolewire

1

80

Frontboard of motorcover

1

81

Sideboard of motorcover

2

82

Archclamp

2

83

Outlet

1

84

Philips self-tapping screw

ST3×25

4

85

Flat washer

Φ14

2

86

Powdermetallurgy Set

ø24xø19xø14x14x3

2

87

Handlebarcover (Upper/L)

1

88

Handlebarcover (Lower/L)

1

89

Hand lebar cover (Upper /R)

1

90

Handlebar cover (Lower /R)

1

91

Front cover

2

92

Philips C.K .S . self-tapping

screw

2

93

Cable guider

2

94

Plastic flat washer

Φ25xΦ18xt3.0

2

95

Plastic flat washer

Φ26xΦ20xt5.0

2

96

Foot cover (Left)

2

97

Foot cover (Right)

1

98

Feet pad

1

Summary of Contents for 6.4

Page 1: ...1 ENG MAXXUS 6 4 Treadmill I N S TA L L AT I O N O P E R AT I N G M A N U A L...

Page 26: ...26 Exploded drawing...

Page 29: ...29 ENG Notes...

Page 30: ...30 Notes...