Page

10

of 18

Copyright 2015 – PT17 / S150209

60.

Hold your elevator at neutral (on the same level as the horizontal stabilizer) and tighten the EZ Link connector onto the

elevator pushrod.

61.

If necessary, cut off the portion of the elevator

pushrod that extends excessively behind the

elevator servo‟s EZ Link connector.

(NOTE: Leave approx.

1/2

-inch of

extra pushrod for possible adjustments).

62.

If you use a glow engine, install your throttle

servo and connect the throttle pushrod between

your engine and throttle servo.

(NOTE: For better appearance and

airframe longevity, we recommend

using an electric power system for

this model. For scale-like flying

using our U638109 motor, 100A

ESC and a 19x6 propeller, you

may use two 4S/4,000 mAh or

above LiPo batteries in series. For

extra power, we recommend using

a 10S or 12S/3,900mAh or above

LiPo battery – or three 4S LiPo

batteries in series, with an 18x8 to

20x8 propeller.)

63.

If you use an electric motor,

confirm or correct its direction

of rotation.

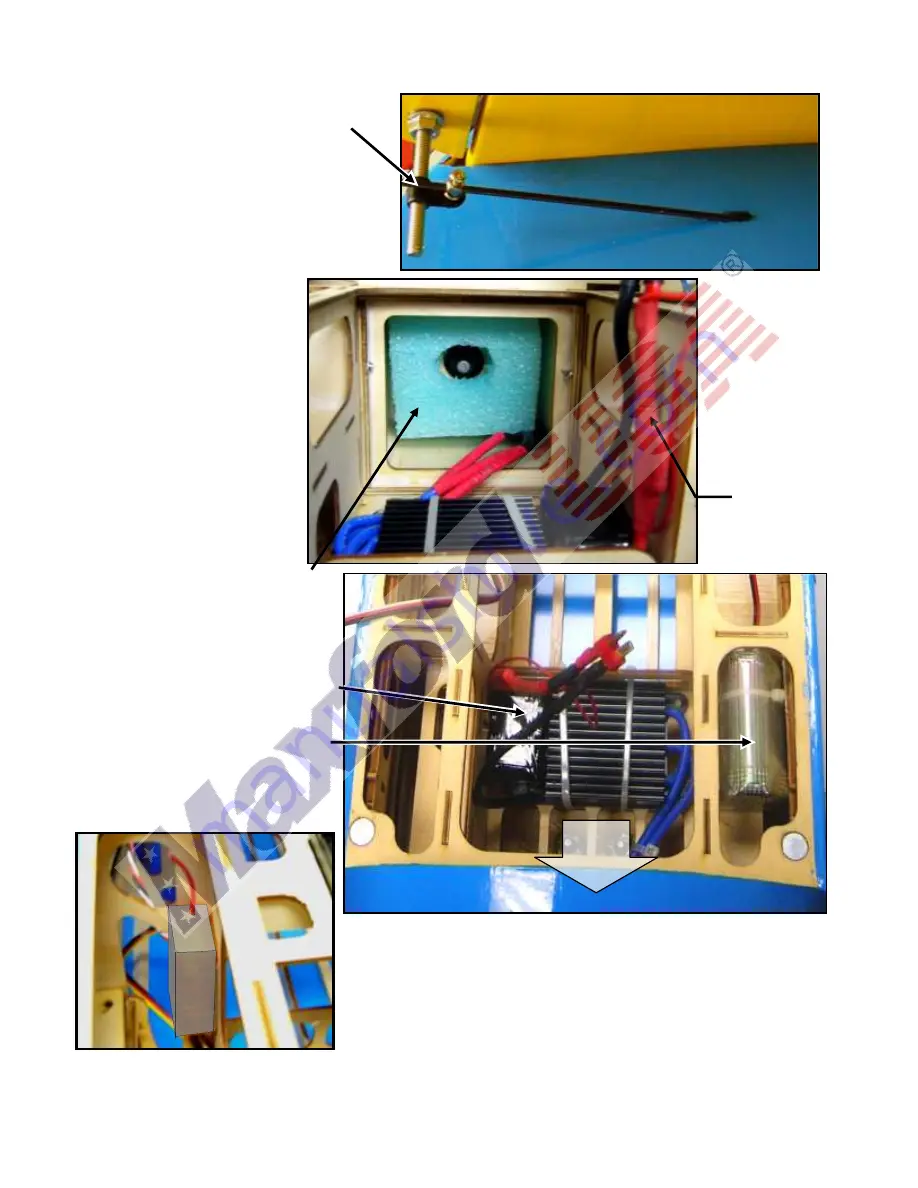

(NOTE: If you are using an electric

power system, inserting some foam

rubber (not included) inside the engine

mounting box may serve as a „safety

cushion‟ for your flight battery.

The PT-17‟s spacious cockpit permits

great flexibility in where you install your

radio and power system components.

During all of our EP flight tests the ESC

was mounted behind and below the

engine mounting box and we secured

our radio‟s battery above and to the left

of the ESC as pictured at the right. Our

receiver was held in position with

double-sided foam tape at the right-hand

side of the servo tray as shown below.

Wait until you are ready to adjust your PT-17‟s center of gravity to decide on the final positions of your batteries.

IMPORTANT:

To avoid

sparks,

always

c

onnect the

ESC to your

flight battery

first,

THEN

connect the

anti-spark

connector.

Nose