20

Secondary of the transformer: Use the table below

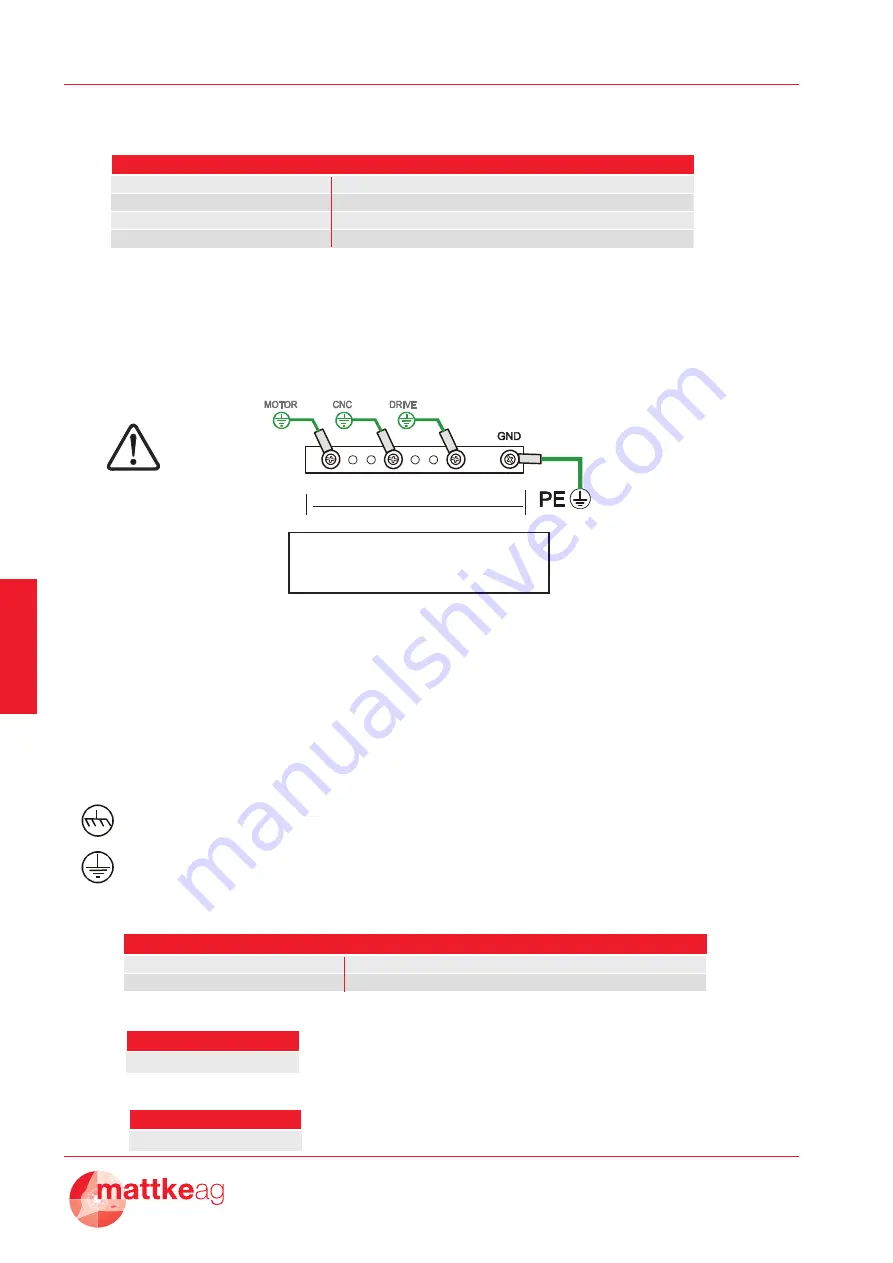

3.1 Connections to earth and ground

Make sure that the servodrive and the motor are connected to earth in accordance with the

current norms. This connection must be done by using a copper bar, mounted on insulating

supports:

Then follow these indications:

1. Connect to the ground bar:

the GND pin 3 of the Dc One

the internal „0V“ zero voltage of the CNC;

the earth terminals of the PLC/CNC frames;

the „0V“ of the auxiliary supply;

2. Connect the ground bar to the zinced panel of the drive by using a screw, then connect

that screw to earth.

3. Connect earth to the motor’s

It suggests a conductive connection as much as possible to the chassis, or the heatsink,

or the mounting panel of the electrical box.

It refers to the earth connection.

Motor and Power cable (as norm EN60204)

Control signals cable (as norm EN60204)

Feedback signals cable (as norm EN60204)

Ground bar

Earth point connection

L bar

Bar's section

0,5 .. 1m

30 x 5 mm

1..2m

40 x 5 mm

Make sure that the servodrive and the motor are connected to earth in accordance with the current

norms. This connection must be done by using a copper bar, mounted on insulating supports:

L bar

then follow these indications:

1. Connect to the ground bar:

the GND pin 3 of the Dc One

the internal "0V" zero voltage of the CNC;

the earth terminals of the PLC/CNC frames;

the "0V" of the auxiliary supply;

2. Connect the ground bar to the zinced panel of the drive by using a screw, then connect that screw

to earth.

3. Connect earth to the motor’s

It suggests a conductive connection as much as possible to the chassis, or the heatsink,

or the mounting panel of the electrical box.

It refers to the earth connection.

SECTION

SIZE (A)

1,5mm

2

/ 15AWG

2/4 4/8 7/14

2,5mm

2

/ 13-14AWG

10/20

SECTION

0,5mm

2

/ 20AWG

SECTION

0,25 - 0,35mm

2

/ 22 -24AWG

Ground bar

Earth point connection

L bar

Bar's section

0,5 .. 1m

30 x 5 mm

1..2m

40 x 5 mm

Make sure that the servodrive and the motor are connected to earth in accordance with the current

norms. This connection must be done by using a copper bar, mounted on insulating supports:

L bar

then follow these indications:

1. Connect to the ground bar:

the GND pin 3 of the Dc One

the internal "0V" zero voltage of the CNC;

the earth terminals of the PLC/CNC frames;

the "0V" of the auxiliary supply;

2. Connect the ground bar to the zinced panel of the drive by using a screw, then connect that screw

to earth.

3. Connect earth to the motor’s

It suggests a conductive connection as much as possible to the chassis, or the heatsink,

or the mounting panel of the electrical box.

It refers to the earth connection.

SECTION

SIZE (A)

1,5mm

2

/ 15AWG

2/4 4/8 7/14

2,5mm

2

/ 13-14AWG

10/20

SECTION

0,5mm

2

/ 20AWG

SECTION

0,25 - 0,35mm

2

/ 22 -24AWG

FUSE F2 (A) SIZE Drive (A)

5

8

12

16

2/4

4/8

7/14

10/20

SECTION SIZE (A)

1,5mm2 / 15AWG

2/4 4/8 7/14

2,5mm2 / 13-14AWG

10/20

SECTION

0,5mm2 / 20AWG

SECTION

0,25 - 0,35mm2 / 22 -24AWG

Summary of Contents for MDCA 100

Page 1: ...1 MDCA XXX XX Precision Servodrive for DC motors...

Page 2: ...2...

Page 4: ...4 MDCA XXX XX...

Page 36: ...36 V 1 0...