Rev.

Descrizione

Redatto/Gestito

Approvato

Cod.Ident.

Pagine

Data Em.

0.6

Manuale Istruzioni

GN

UTEC

B041.M01.EN

34

/47

07/2014

analog channel.

•

Press the button

to access the screen on.

•

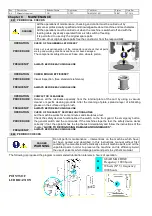

Place the mold on the scale

Press the button to tare.

Pour the material into the mold and wait for the reading to

stabilize.

Confirm the value

Test execution

14. Make sure that the machine is in ready state (icon

in the status bar).

15. Touch the icon

to start the gyratory compaction.

ATTENTION

After touching the icon

the piston will start moving downwards. If the mould

has not been positioned correctly, the piston will not be able to complete its travel.

The machine will detect this condition and makeautomatically another attempt. If this secondattempt fails, the

“pause” function will be activated (icon:

displayed on the status bar) and the operator has to open the safety

door and adjust the mould (the execution of the test is not interrupted). When the safety door is closed, the machine

will give a third try and, in case of error, will stop the test with an acoustic alarm.

16. The screen of the compaction will be displayed (numeric

visualizazion); the screen will report the values of the

external angle, of the load and of the specimen height

at every single rotation.

If the compaction is not performed properly, the load

value could be shown in red. This occurs if the load value

does not respect, even for one single rotation, the

tolerance values set in the parameters configuration

screen.

17. Touch the button to alternate the numeric

visualization with the graphic one, and vice

versa, during the compaction phase.

18. The graphical display modes are displayed on a single

graph, trends, lap by lap, height (track RED) and density

(track GREEN) of the specimen.

19. Touch the button

to alternate on the y-axis the

visualization of the scale of the three lines

20. Press anytime the button

to stop the test.