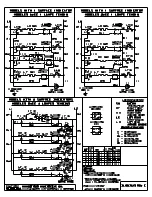

Primary air distance “A”

Methane gas G20

Liquid gas G30/G31

TABLE 1

Model

Category

Construction type

Air necessary for combustion

Nominal thermal power

Minimum thermal power

Overall thermal power (gas)

Connection pressure

Methane gas 2H

Liquid gas 3+

Gas connection values

Methane gas 2H

Liquid gas 3+

Nozzles Ø 1/100 mm

Main burner

G20

G30/G31

(HuB = 9.45 kWh/m

3

) in m

3

/h

(HuB = 12.87 kWh/kg) in kg/h

Nominal thermal power

Minimal thermal capacity

Nominal thermal power

Minimal thermal capacity

G20

G30/31

20 mbar

28/37 mbar

II2H3+

A

m

3

/h

kW

kW

No. of nozzles, pilot burner

G20

G30/G31

Electrical data

Electric oven power:

Voltage:

No. of cables per section:

Hour consumption

G20

m

3

/h

G25

m

3

/h

G30/G31

kg/h

8

1

B

Ø 70

5

2.5

0.7

0.265

0.196

120

Adjustable

80

40

-

-

8

3

C

Ø 90

7

3.5

0.9

0.370

0.274

0.370

0.274

145

Adjustable

95

40

-

-

7

Open

145

Adjustable

100

45

-

-

-

-

Gas oven

GN 1/1

6.0

3.0

1.4

0.317

0.235

135R

Adjustable

85

70

-

-

Open

Open

Gas oven

GN 1/1

ventilated

7.5

3.6

0.75

0.381

0.282

155

Adjustable

100

48

-

-

-

-

Gas oven

GN 2/3

5

2.2

0.8

0.233

0.172

115 R

Adjustable

75

48

-

-

CC80G

40 W

73 W

V AC 230 3 50 Hz

V AC 230 3 50 Hz

3 x 1.5 mm

2

3 x 1.5 mm

2

-

-

-

ABA20001

ABA20003

14.2

15.6

21.6

kW

kW

kW

Solid

Gas range

5

3.5

1.2

1,50

1,65

2,28

1,11

1,22

1,69

024-03 - Gas cooker

5