29

28

NOTE:

Only overcut on the bottom or underneath side of the material being cut.

NOTE:

Make sure bevel table is locked firmly in place before beginning cut.

30

1

4

30

1

model no. 055-6789-8 | contact us 1-800-689-9928

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

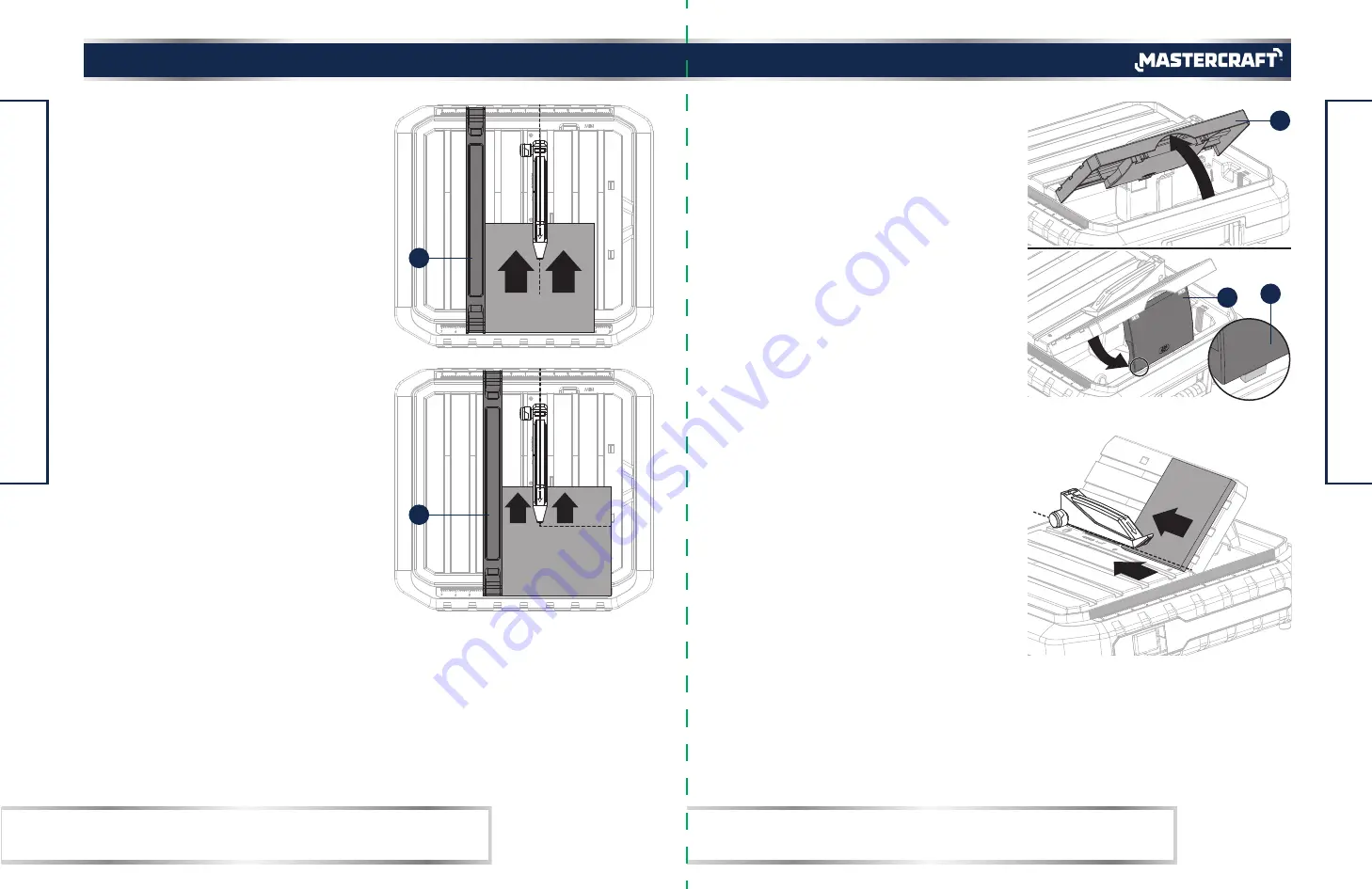

Fig. 17a

Fig. 17b

Fig. 18a

Fig. 18b

MAKING A BEVEL CUT (Fig. 18a-18b)

Bevelled 45° cuts can be made using the bevel table.

•

Using a marker or grease pencil, mark the area to be

cut on material.

• Remove the rip guide.

• Tilt the bevel table (4).

•

On underside of the bevel table, pull down the table

holder (30) and position in the locators.

• Turn the on/off switch to the ON position.

•

Let the cutting wheel build up to full speed and wait for

the wheel to get wet before moving the material into

the wheel.

•

Hold the material firmly against the bevel table and

feed the material into the cutting wheel.

•

When the cut is made, turn the saw OFF. Wait for the

cutting wheel to come to a complete stop before

removing any part of the material.

MAKING AN L-CUT (Fig. 17a-17b)

L-cuts are cuts that remove a piece of tile to fit in a corner,

around a cabinet, or a piece of moulding and are made by

making two separate cuts.

•

Using a marker or grease pencil, mark the area to be cut

on material.

• Remove the mitre gauge.

•

Place the material on the table, firmly against the rip

guide (1).

•

Make sure the material is clear of the cutting wheel

before turning on the saw.

• Turn the on/off switch to the ON position.

• Let the cutting wheel build up to full speed and wait for

the wheel to get wet before moving the material into the

wheel.

•

Hold the material firmly against the rip guide and feed

the material into the cutting wheel.

•

Make the cut far enough into the material without

overcutting.

•

When the cut is made, turn the saw OFF. Wait for the

cutting wheel to come to a complete stop before removing

any part of the material.

•

Turn the material over and make the second cut along

one of the marks. This time overcut the other line, and

the cut piece should separate from the rest of the material.

•

When the second cut is made, turn the saw OFF. Wait

for the cutting wheel to come to a complete stop before

removing any part of the material.