Technical information

M

Z

010

English

2

82

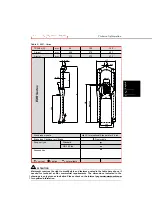

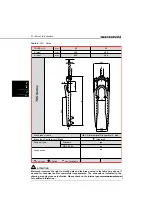

Table 4:

Drop Off Comp Series

ATTENTION

Marzocchi reserves the right to modify data and features quoted in the table here above, if

needed for technical and/or commercial requirements. The dimensions indicated in the

drawing are only given as indicative. Please check on the internet page www.marzocchi.com

for updated information.

181

Max 68

ø 30

100

130

18

ø 32

A

C

Max 345

352

A (max)

A (min)

TRAVEL (C)

mm

mm

mm

Disk brake mounts

Brake type Cantilever or V-Brake

Drop out type

Standard

QR 20 Plus

Accessories

XC International Standard for 6” disk

Integrated fender

Dr

op-Off Comp Series

= current

= option

= not available

498

388

110

518

388

130

Summary of Contents for QR20 Plus

Page 1: ...MODEL YEAR 2004 ...

Page 2: ......

Page 7: ...MZ010 Use and maintenance instruction manual English ...

Page 34: ...MZ009 181 MARZOCCHI distributors and service centers ...

Page 38: ......