Triplematic

Triplematic 201708 EN 29

Operation

10. Turn the grinding speed knob to set the desired

speed for the machine.

IMPORTANT If the metal of a cutter turns blue

during grinding, the speed is set too high and

the metal is overheated. This can cause the

metal in the cutter to lose its properties. Replace

the damaged cutter or re-sharpen the chain.

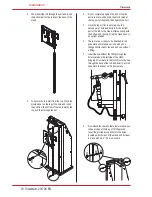

11. Fold the grinding head down to its grinding

position.

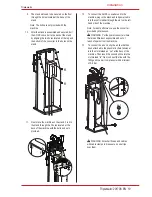

12. The grinding depth for gullets is recommended

by the chain manufacturer. To set it, turn the

grinding depth knob, located on the back of the

grinding head:

• clockwise, to grind shallower into the gullet, or

• counter-clockwise, to grind deeper into the

gullet.

13. Set the cutter top plate to equal lengths. If the

right (outer) and left (inner) cutters are not

sharpened to equal lengths, follow these steps:

• Do a sharpening test on a test chain,

according to the instructions in section 8.2,

“Sharpening test”.

• Make sure that the right and left cutting

teeth are sharpened to equal lengths. Use

the template provided with the machine to

measure. If they are not equally long, turn the

equal cutting teeth knob:

– clockwise to increase the length of the right

cutter and decrease the length of the left

cutter, or

– counter clockwise to decrease the length of

the right cutter and increase the length of the

left cutter.

• Repeat the sharpening test until the cutter top

plates are sharpened to equal lengths.

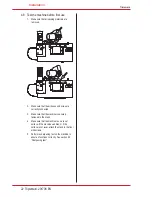

14. The diameter of the grinding wheel decreases

when it is used. To maintain the grinding

proportions, the grinding wheel position must

be changed when:

• the grinding wheel has been worn, or

• the chain has a different pitch that requires a

different wheel. The grinding wheel centering

knob is used to center the grinding wheel

over the chain. The gullets should have equal

depth on the left and right cutting links.

– Sharpen a few links and then visually

inspect the result. If the grinding depth is

not equal on the gullets of the right and left

cutting links, continue to the next step.

– Turn the grinding wheel centering knob to

move the grinding motor and the wheel up

or down. Set the arrow on the scale to

point to the number that corresponds to the

wheel diameter, as displayed below. These

scale numbers are approximate and are

only for general guidance. Observe if the

grinding depth of right and left gullets are

equal for final adjustment.

Grinding wheel diameter:

Scale:

5.9

"

(150 mm)

(new grinding wheels)

1-3

5.5

"

(140 mm)

3-5

5.1

"

(130 mm)

4-6