3 - 29

G1/3

G1/2

G - OCCASIONAL MAINTENANCE

G1 - F

UEL SUPPLY CIRCUIT

PURGE

This series of operations should only be performed in the following case:

- A component in the supply circuit has been replaced or drained.

Ensure that there is enough fuel in the tank and turn the ignition key to

position 2 to switch on the electrical systems.

- Open the left-hand cover.

PURGING THE FUEL FILTER

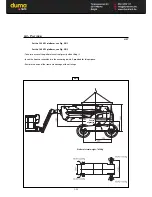

- Loosen the purge screw 1 (Fig. G1/1)

- Operate the priming bulb 2 (Fig. G1/2) until the fuel flows air-free from the

purge scre

- Tighten the purge screw 1 (Fig. G1/1) while the fuel is still flowing.

PURGING THE INJECTORS

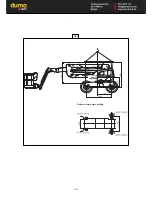

- Loosen the hose connections 3 (Fig. G1/3) on one of the injectors.

- Press the starter until the diesel flows air-free from the hose connections 3

(Fig. G1/3).

- Tighten the hose connections while the fuel is still flowing

Do not engage the starter motor on a continual basis for more than 30

seconds and let it cool between unsuccessful attempts.

- The engine is now ready to be started.

- Turn the I.C. engine over slowly for 5 minutes immediately after bleeding the

fuel feed circuit, in order to ensure that the injection pump has been bled

thoroughly.

NOTE :

If the I.C. engine functions correctly for a short time then stops or

functions irregularly, check for possible leaks in the low pressure circuit. If in

doubt, contact your dealer.

3

3

3

3

2

G1/1

1

Summary of Contents for 160 ATJ

Page 2: ......

Page 4: ......

Page 6: ......

Page 7: ...1 1 1 OPERATING AND SAFETY INSTRUCTIONS 1 OPERATING AND SAFETY INSTRUCTIONS...

Page 8: ......

Page 25: ...1 19 REAR AXLE ASSEMBLY FIG E Axle type Serial Nr Maker s N E...

Page 28: ...1 22...

Page 29: ...2 1 2 DESCRIPTION 2 DESCRIPTION...

Page 30: ......

Page 31: ...2 3...

Page 37: ...2 9...

Page 39: ...2 11...

Page 41: ......

Page 74: ...2 46 MAIN DISTRIBUTOR Basket rotation Turret rotation Steering Pendular arm Tilt compensation...

Page 75: ...3 MAINTENANCE 3 MAINTENANCE...

Page 76: ......

Page 78: ......

Page 105: ...3 31...

Page 107: ...3 33 G3 2 Centre of gravity Platform s total weight 8090 Kg...

Page 111: ...4 ELECTRICITY 4 ELECTRICITY 4 1...

Page 112: ...4 2...

Page 114: ...4 4...

Page 115: ...5 1 5 OPTIONAL ACCESSORIES FOR THE RANGE 5 OPTIONAL ACCESSORIES FOR THE RANGE...

Page 116: ...5 2...

Page 120: ...5 6...

Page 121: ...6 1 6 MAINTENANCE HANDBOOK 6 MAINTENANCE HANDBOOK...

Page 122: ......

Page 130: ......

Page 131: ...Powered by TCPDF www tcpdf org...