1

2

3

4

Removing and installing piston rings

123

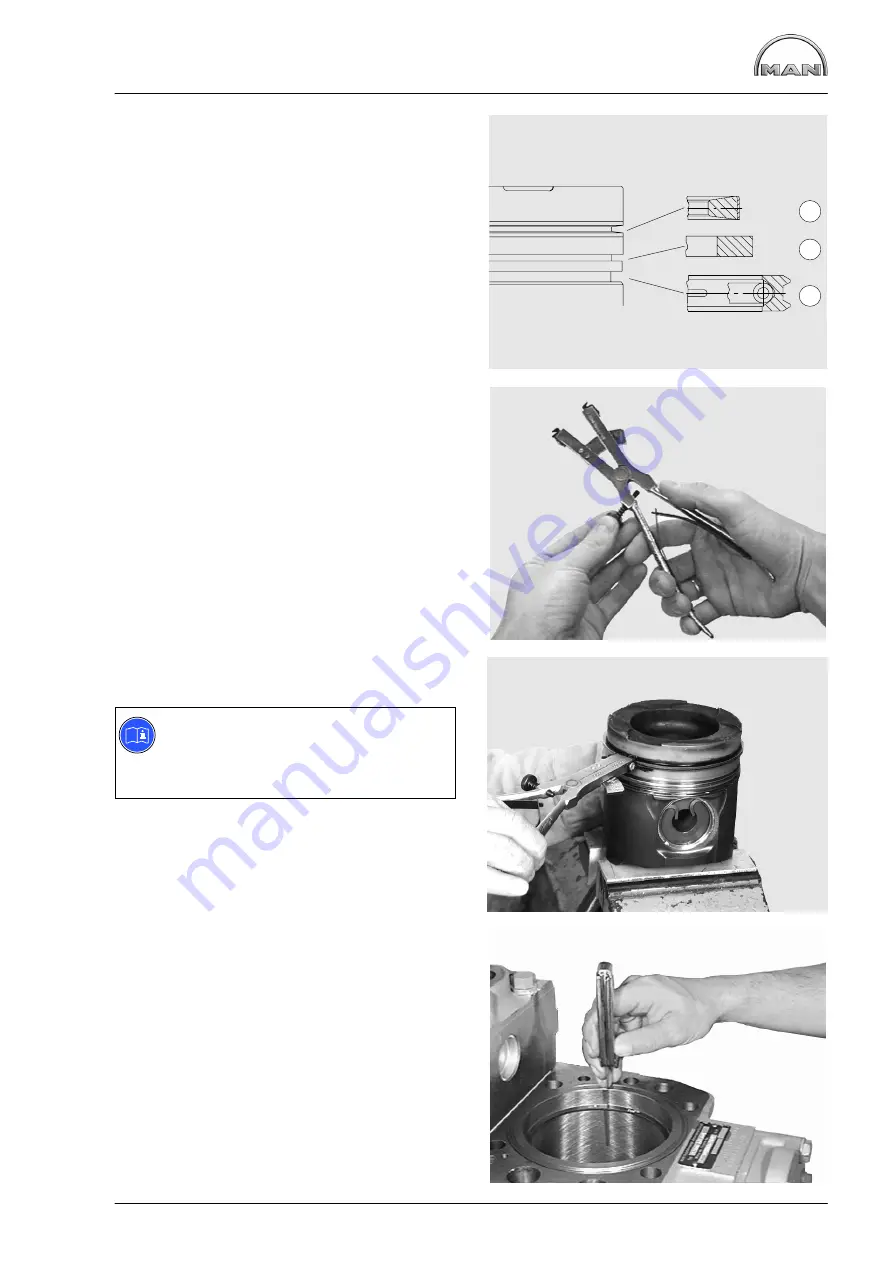

Piston ring arrangement

Fig. 1

À

Compression ring (double

−

sided keystone ring)

Á

Compression ring (tapered compression ring)

Â

Oil scraper ring (bevelled

−

edge ring)

Removing piston rings

Fig. 2

Remove pistons with conrods.

Fit conrod in a vice, use protective jaws.

Set piston ring wrench to piston diameter.

Fig. 3

Apply piston ring wrench to piston ring joint and

disengage the piston ring from the piston ring

grooves.

Note:

The coiled spring expanders mean that the

oil scraper ring has greater tangential ten-

sion.

Carefully clean the piston ring grooves using saw-

dust. Do not damage the piston ring grooves.

Checking ring end clearance

Fig. 4

Insert the piston rings individually in the cylinders

and use a feeler gauge to determine the ring end

clearance.

If the ring end clearance is too great, replace the

piston rings.

Ring end clearance, see “Service Data”.

2

1

3

Summary of Contents for D 2842 LE 620

Page 1: ......

Page 2: ......

Page 20: ...Engine views D 2842 LE 620 18 7 1 2 4 3 5 6 7 1 2 4 11 9 10 8...

Page 136: ...134...

Page 137: ...135 Service Data...

Page 163: ...161 Special tools...

Page 164: ...Special tools 162 1 2 3 4 5 6 7 8 9 10 11 11 1 11 2 12 12 1 12 2 13 14...

Page 166: ...Special tools 164 15 1 15 2 15 3 15 4 15 5 1 2 7 15 6 3 4 5 6 15 7...

Page 170: ...Special tools 168 3 1 4 29 5 6 2 29 30 31 32 33 34 35...

Page 172: ...Special tools 170 36 37 38 39 42 40 41 44 2 44 1 44 43 1 43 2 43 3 43 45 46...

Page 178: ...176...

Page 179: ......

Page 180: ......