1

2

3

4

Refacing valves

99

Fig. 1

Apply abrasive paste to the tapered area of the

valve seat.

Lubricate the valve guide and insert the valve.

Fig. 2

Use a valve grinder to reface the valve seat by ap-

plying moderate axial pressure and describing a

turning motion.

Note:

Keep the valve stem and the valve guide

free of abrasive paste.

Fig. 3

The valve seat must have a faultless, contained

grinding pattern.

The grinding pattern width is correct if the valve

seat insert is in order.

À

Valve tapered area

Á

Valve seat

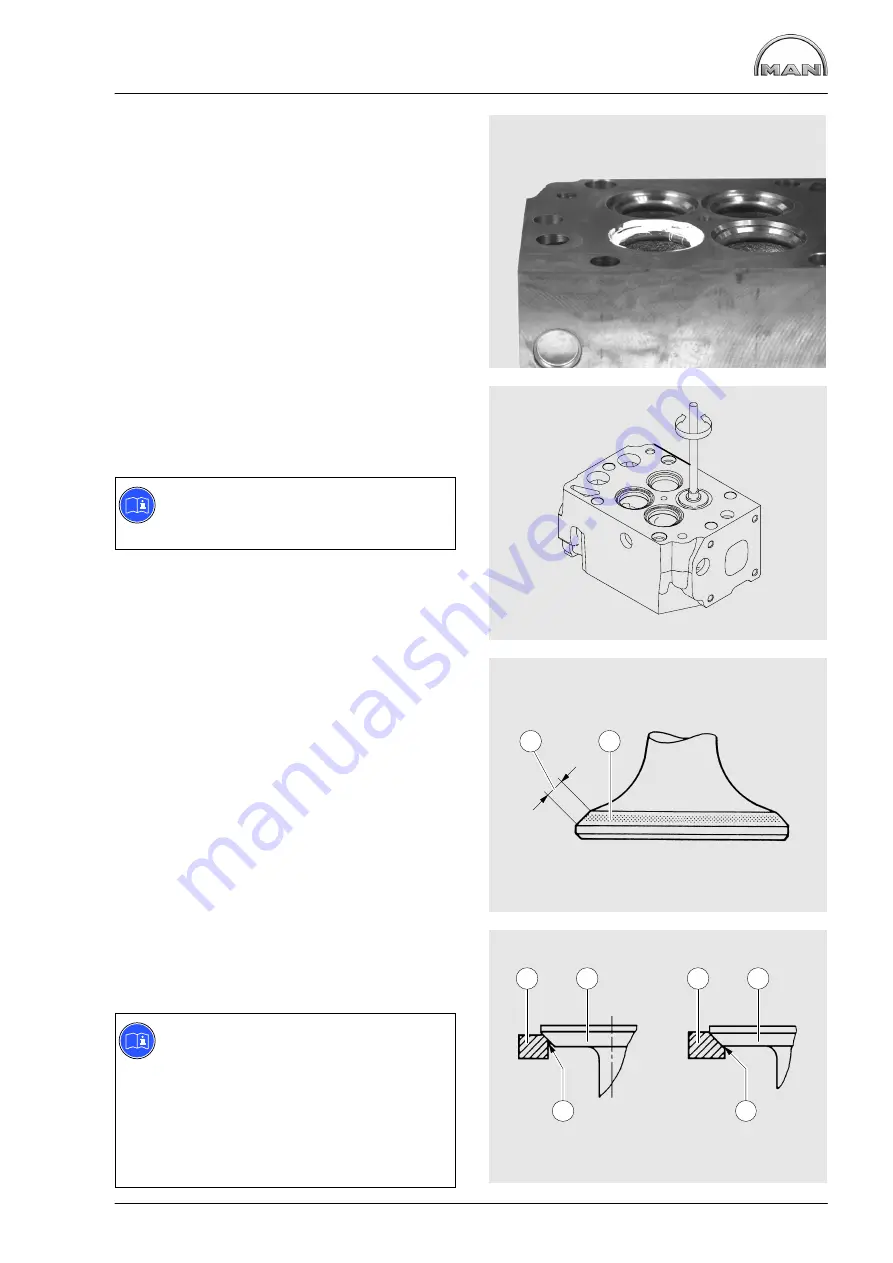

Fig. 4

À

Valve seat insert

Á

Valve

Â

Valve seat too wide

Ã

Valve seat good

Note:

Valve seats which are too wide tend to

accumulate coking residues,

−

valves start to leak

−

Valve seats which are to narrow prevent

rapid dissipation of heat from the valve

plate to the cylinder head,

−

valves burn

−

2

1

1

2

1

2

3

4

Summary of Contents for D 2842 LE 620

Page 1: ......

Page 2: ......

Page 20: ...Engine views D 2842 LE 620 18 7 1 2 4 3 5 6 7 1 2 4 11 9 10 8...

Page 136: ...134...

Page 137: ...135 Service Data...

Page 163: ...161 Special tools...

Page 164: ...Special tools 162 1 2 3 4 5 6 7 8 9 10 11 11 1 11 2 12 12 1 12 2 13 14...

Page 166: ...Special tools 164 15 1 15 2 15 3 15 4 15 5 1 2 7 15 6 3 4 5 6 15 7...

Page 170: ...Special tools 168 3 1 4 29 5 6 2 29 30 31 32 33 34 35...

Page 172: ...Special tools 170 36 37 38 39 42 40 41 44 2 44 1 44 43 1 43 2 43 3 43 45 46...

Page 178: ...176...

Page 179: ......

Page 180: ......