7

3.

Set the adjusting plate/set plate on the gauge base

so that the planer blade locating lugs on the set

plate rest in the mini planer blade groove, then

press in the heel of the adjusting plate flush with

the back side of the gauge base and tighten the

screws.

4. It is important that the blade sits flush with the

inside flank of the gauge plate, the planer blade

locating lugs sit in the blade groove and the heel of

the adjusting plate is flush with the back side of the

gauge base. Check this alignment carefully to

ensure uniform cutting.

5.

Slip the heel of the adjusting plate into the groove

of the drum.

Fig.9

6.

Set the drum cover over the adjusting plate/set

plate and screw in the three bolts so that a gap

exists between the drum and the set plate to slide

the mini planer blade into position. The blade will

be positioned by the planer blade locating lugs on

the set plate.

7.

The blade's lengthwise adjustment will need to be

manually positioned so that the blade ends are

clear and equidistant from the housing on one side

and the metal bracket on the other.

8. Tighten the three bolts (with the socket wrench

provided) and rotate the drum to check clearances

between the blade ends and the tool body.

9.

Check the three bolts for final tightness.

10. Repeat procedures 1 - 9 for the other blade.

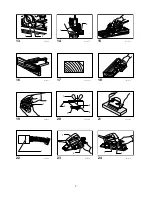

For the correct planer blade setting

Your planing surface will end up rough and uneven,

unless the blade is set properly and securely. The blade

must be mounted so that the cutting edge is absolutely

level, that is, parallel to the surface of the rear base.

Refer to some examples below for proper and improper

settings.

(A)

(B)

(B)

(A)

(B)

(A)

(A) Front base (Movable shoe)

(B) Rear base (Stationary shoe)

Correct setting

Nicks in surface

Gouging at start

Gouging at end

Although this side view cannot

show it, the edges of the blades

run perfectly parallel to the rear

base surface.

Cause: One or both blades fails to

have edge parallel to rear

base line.

Cause: One or both blade edges

fails to protrude enough in

relation to rear base line.

Cause: One or both blade edges

protrudes too far in relation

to rear base line.

EN0004-1

Connecting a vacuum cleaner (for European

countries only)

Fig.10

When you wish to perform clean planing operation,

connect a Makita vacuum cleaner to your tool. Then

connect a hose of the vacuum cleaner to the nozzle as

shown in the figures.

OPERATION

Hold the tool firmly with one hand on the knob and the

other hand on the switch handle when performing the

tool.

Planing operation

Fig.11

First, rest the tool front base flat upon the workpiece

surface without the blades making any contact. Switch

on and wait until the blades attain full speed. Then move

the tool gently forward. Apply pressure on the front of tool

at the start of planing, and at the back at the end of

Summary of Contents for MT191

Page 11: ...11 11 12 13 14 15 16 17 Makita 18 Fig 1 Fig 2 Fig 3...

Page 12: ...12 Makita Fig 4 Fig 5 Fig 6 Fig 7 1 Fig 8 2 3 4 5 Fig 9 6 7 8 9 10 1 9...

Page 13: ...13 A B B A B A EN0004 1 Fig 10 Makita Fig 11 Fig 12 Fig 13 Fig 14 Fig 15 9 Fig 16...

Page 14: ...14 Fig 17 Fig 18 V Fig 19 Fig 20 D Fig 21 2 3 Fig 22 Fig 23 Fig 24...

Page 48: ...48 Makita Corporation Anjo Aichi Japan www makita com 885032 979...