P 3 / 11

R

epair

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Poly V-belt 4-241

DISASSEMBLING

ASSEMBLING

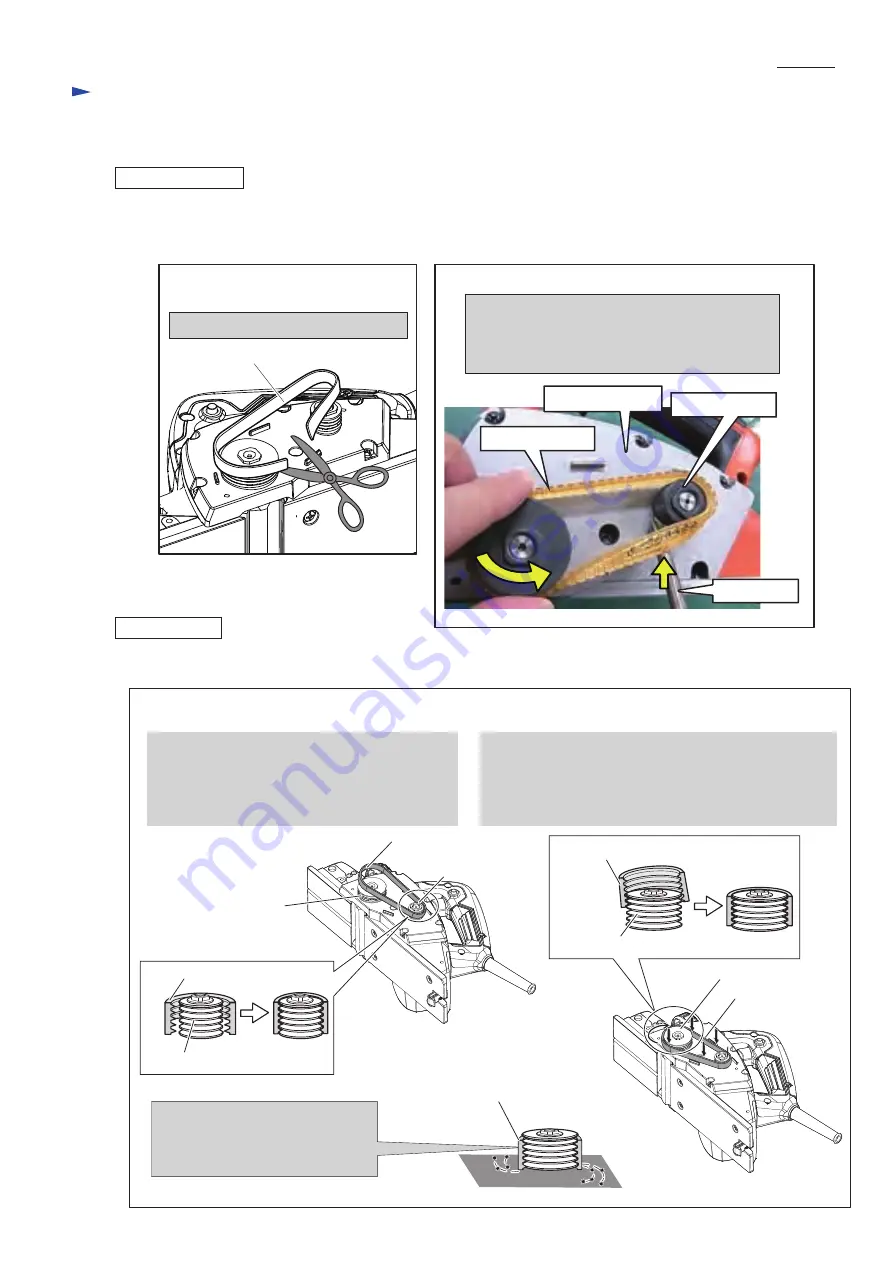

(1) Disassemble Belt cover.

Remove Belt cover and then remove Poly V-belt 4-241 as illustrated in

Fig. 2

in case of replacing the Poly V- belt only.

In case of replacing Armature, Ball bearings or Drum, remove the Poly V-belt as illustrated in

Fig. 2A

.

Cut Poly V-belt 4-241.

Fig. 2

Fig. 2A

Poly V-belt 4-241

Poly V-belt 4-241

Screwdriver

Bracket complete

V Pulley 4-20L

1. Engage all V-shaped ribs of Poly V-belt 4-241

with the grooves of V-pulley 4-20L (small one).

And engage some of V-shaped ribs of the same

of the Poly V-belt with the groove of V-pulley

4-37 (large one).

2. Turn V-pulley 4-37 (large one), while pressing

the V-belt toward Bracket complete, until all

V-shaped ribs of Poly V-belt 4-241 with the grooves

of V-pulley 4-37 (large one). Now, Poly V-belt and

both of V-pulleys engage each other.

Poly V-belt 4-241

V-Pulley 4-20L

Poly V-belt 4-241

Poly V-belt 4-241

V-Pulley 4-20L

V-Pulley 4-37

Bracket complete

V-pulley 4-37

Poly V-belt 4-241

< Note >

Be careful,

not to push so deep that

Poly V-belt 4-241 rubs against

Bracket complete.

Poly V-belt 4-241

V-pulley 4-37

(1) Mount Poly V-belt 4-241 as illustrated in

Fig. 3

.

Fig. 3

1. Insert screwdriver under Poly V-belt 4-241.

2. Lever up the Poly V-belt with the screwdriver,

while turning any of two V-pulleys.

Now, Poly V-belt 4-241 is removed.