R

epair

P 4 / 8

< 5 > Removing ball bearing 6002DDW and ball bearing 6202LLB on drum

< 6 > Mounting armature

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

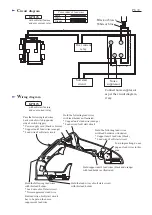

(2) Mount poly V-belt. See Fig. 5.

(3) Fasten hex socket head bolt M6x12 and hex nut M10-17 firmly until both V-pulleys turn as illustrated in Fig. 6.

(1) To protect the screw hole for hex socket head bolt M6x12, insert a screw of size M6 as illustrated in Fig. 7.

(1) Make sure that O ring 14 has been mounted to armature. If not, mount it. And then, mount coupling with

aligning its spline with the armature's spline. See Fig. 9.

(2) Remove ball bearing 6202LLB with No.1R269 "Bearing extractor". See Fig. 8.

(3) Remove ball bearing 6002DDW with No.1R269 "Bearing extractor". See Fig. 8.

Poly V-belt

Hex wrench

Turn the hex wrench clockwise

for fastening.

Turn the wrench

anti-clockwise

for fastening.

Wrench 17

Ball bearing 6202LLB

Ball bearing 6202LLB

Screw of size M6

1R269 "Bearing extractor"

1R269 "Bearing extractor"

Ball bearing 6002DDW

Ball bearing 6002DDW

Drum

Drum

O ring 14

Armature

Armature equipped with O ring 14

Coupling

carved Spline