R

epair

P 3 / 8

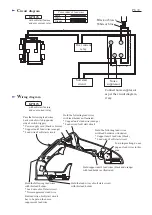

< 3 > Removing V- Pulleys

(1) Attach the following bit to the impact driver.

*

1R230 Multi-purpose M6 for hex socket head bolt M6x12

* Socket bit 17 for hex nut M10x17.

And remove hex nut M10x17 and hex socket head bolt M6x12

with the impact driver.

(2) Remove V-pulley 9-39.7. And by turning clockwise, remove V-pulley 9-23L. See Fig. 3.

(1) Mount V-pulley 9-23L to the threaded portion of spindle by turning anti-clockwise with your hand.

But be careful, not to tight it too strong. And then, fix the V-pulley 9-23L with hex nut M10x17.

The hex nut M10x17 has to be turned anti-clockwise for fastening. But fasten the hex nut not strong

in this stage. See Fig. 4.

(2) After inserting key 4 to the grove of drum shaft, mount V-pulley 9-39.7 to the drum shaft aligning its cut portion

to the key 4. And then, fix the V-pulley 9-39.7 with hex socket head bolt M6x12.

The hex socket head bolt M6x12 has to be turned clockwise for fastening. But fasten the hex socket head bolt

not strong in this stage. See Fig. 4.

< 4 > Mounting V-pulleys and poly V-belt

Fig. 2

Fig. 3

Fig. 4

Hex nut M10x17

Hex socket head

bolt M6x12

< Note in Removing >

* Turn hex nut M10x17 clockwise for loosening.

* Adhesive has been applied on hex socket head

bolt M6x12.

< Note in Removing >

* Pay attention, not to lose key which is mounted to

drum shaft.

D=5mm

110mm

D

13mm

1R230 Multi-purpose M6

V-pulley 9-39.7

V-pulley

9-23L

Key 4

Turn clockwise for

loosening.

Hex nut M10x17

Hex socket head

bolt M6x12

Key 4

V-pulley 9-39.7

V-pulley 9-23L

<Note>

If you use the used hex socket head bolt M6x12,

apply the adhesive to the threaded portion of the bolt,

or use the fresh one.