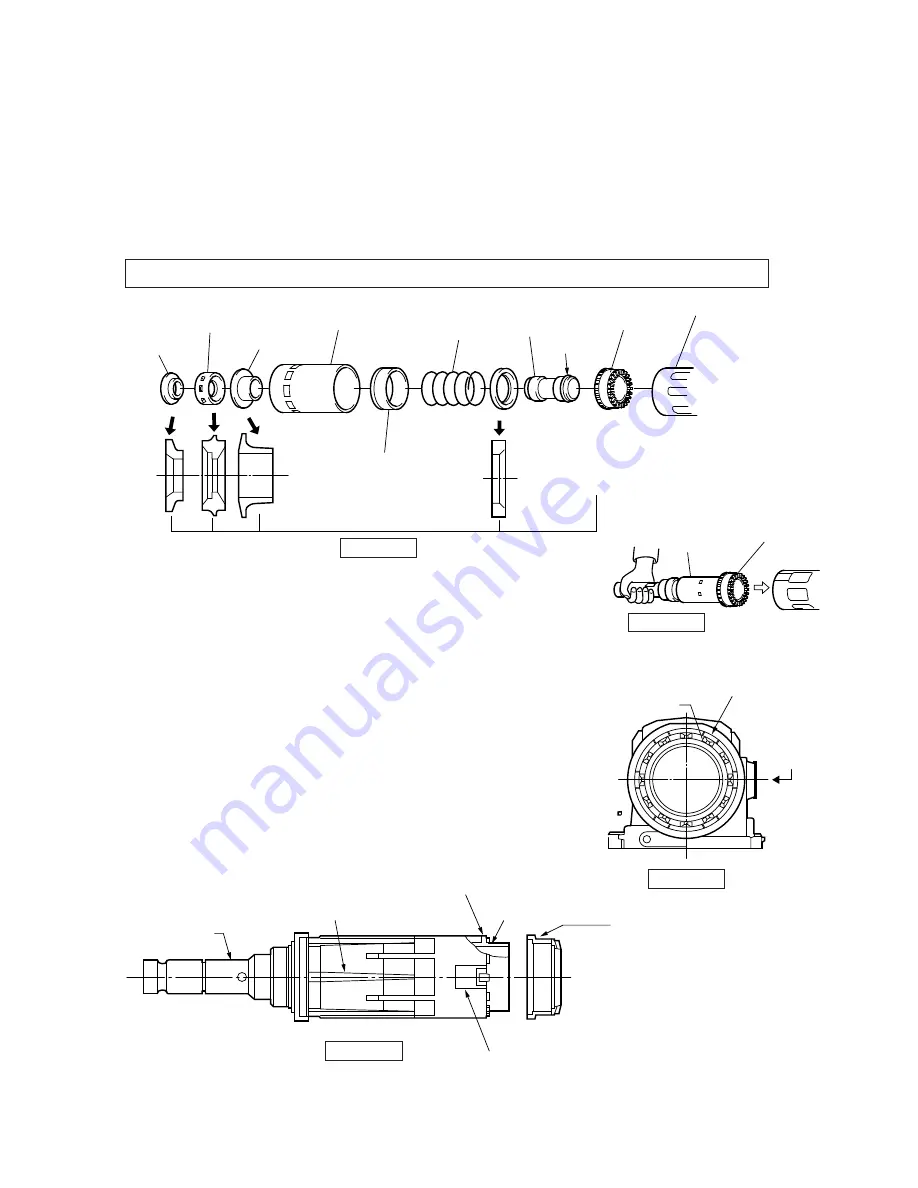

a. Set the parts described below into the crank housing.(See the figure 20.)

b. To set the spiral bevel gear 41, use the tool holder without mounting the lock sleeve for smooth setting.(See the figure 21.)

•Striker(mounted with O ring 34)

•Washer 45

•Ring 45

•Flanged sleeve 22

•Ring 22

•Spiral bevel gear 41

•Compression spring 46

•Slide sleeve

•Rubber ring

Note ) Use care that the washer 45, Flanged sleeve 22, rubber ring 24, ring 22 and striker have each direction.

Figure 20

Ring 22

Rubber ring

Flanged sleeve

Slide sleeve

Compression

spring 46

Striker

O ring 34

Spiral bevel

gear 41

Crank housing

Washer 45

Ring 45

Use care of each direction.

Figure 21

Figure 22

Figure 23

Tool holder

Spiral bevel gear 41

a. Assemble Tool holder B and Spiral bevel gear 41,

matching the cams of both parts.(See the figure 23.)

b. Turn Spiral bevel gear 41 to match dent portions on the can

with grooves on Crank housing. (see the figure 22.)

c. Match the cam on Lock sleeve A to the cam on Tool holder B.

(see the figure 23)

d. Match the flat portion of Lock sleeve A to the mounting side of Change

lever. fit the 6 protruded portions on Lock sleeve B to the 6 grooves on

Crank housing, and then insert the tool holder into Crank housing.

(see the figurt 23.)

12 dent portions

on the cam of the

spiral bevel gear 41

6 grooves on the

crank housing

Mounting side

of the change

lever

Tool holderA

6 protruded portions

on the lock sleeve B

Cam on the lock sleeve A

Cam on the tool holder B

Cam on the spiral

bevel gear 41

Flat portion of lock sleeve B

Assembling the tool holder

Inserting Tool holder(Same as HR4000C)