R

epair

P 12 / 18

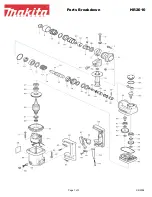

< 12 > Disassembling swash bearing

1. Referring to at page 8, disassemble the product in the order of Fig.4, Fig.4A and Fig.4B at page 8.

And separate inner housing together with tool holder section and swash bearing section from gear housing as

illustrated in Fig. 8C. Ball baring 606ZZ can remain in gear housing in this stage. If so, refer to Fig. 8H at page 13.

2. Separate tool holder section from inner housing as illustrated in Fig. 8D.

Fig. 8C

Inner housing

Plastic

hammer

Tool holder section

Inner housing

Inner housing

Tool holder section

Flat washer 28

Fig. 8D

Fig. 8E

Fig. 8F

Piston cylinder

Swash bearing section

Swash bearing section

Fat washer 5

Compression spring 6

Stop ring E-4

Pin of inner housing

Piston cylinder

3. Disassemble stop ring E-4, flat washer 5 and compression spring 6 with which change plate is fixed, from the pin

of inner housing as illustrated in Fig. 8E.

4. Swash bearing section is held in inner housing with bearing retainer which is fastened with 2 pcs. of hex socket

head bolts M4x12. Take off these hex socket head bolts M4x12 for disassembling swash bearing section.

5. Bring piston cylinder to the dead point. And , twist the the swash bearing section, with pulling off them

from inner housing. Then swash bearing section and change plate can be disassembled from piston cylinder.

See Fig. 8G.

Hex socket head bolts M4x12

Fig. 8G

*Ball bearing 606ZZ

Piston cylinder

Change plate

Change plate