8-3

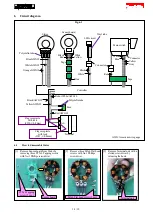

Flowchart of Troubleshooting

Check the items from the top of the following list. (Description of the item is referred to Circuit diagram in

Fig. 6-1

.)

After corrective action, return to the start of Troubleshooting and re-check again.

Symptom

Cause

Corrective action

No

Controller is broken.

Replace Controller.

Does Tester indicate 0.7V ~ 0.9V?

When tester cannot be prepared, go to “Yes”.

Yes

The machine

works properly.

Yes

No

Controller is broken.

Replace Controller.

No

Connectors are in

incomplete connection.

Replace Controller.

Rotation speed

can be changed.

Forward/ Reverse

rotation are OK.

Lead wires are broken.

Check Lead wires, or

replace them.

Switch is broken.

Replace Switch.

No

Connectors are in

incomplete connection.

Replace Controller.

LED job light are

on.

Lead wires are broken.

Check Lead wires, or

replace them.

LED circuit is broken.

Replace LED circuit.

Switch is broken.

Replace Switch.

Yes

Yes

Switch is broken.

Replace Switch.

Terminal is broken.

Check Terminal, or replace

it.

Controller is broken.

Replace Controller.

No

No

Connectors are in

incomplete connection.

Replace Controller.

LED job light are

on.

Lead wires are broken.

Check Lead wires, or

replace them.

Switch is broken.

Replace Switch.

LED circuit is broken.

Replace LED circuit.

Controller is broken.

Replace Controller.

Rotor is broken.

Replace Rotor.

Stator is broken.

Replace Stator.

No

Yes

Rotor is rubbed to

Stator.

Yes

Yes

Motor runs when the

machine is switched on.

In case of running

inconstantly, go to “No”.

Yes

No

Controller is broken.

Replace Controller.

The machine shows same symptom in spite

of the above corrective actions.

LED indicator

lamps are on.

LED indicator

lamps are on.

18 / 19