P

8

/ 1

2

R

epair

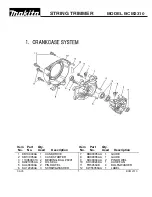

[3] DISASSEMBLY/ ASSEMBLY

[3]-4. Rotor, Stator (for all models)

[3]-5. Replacing Indicator (for all models)

[3]-5. Replacing Link plate (only for BBC231U and AT-3623)

Insert Rotor into Stator slowly so as not to scratch the inside of Stator.

Note: 1. Hold them firmly and carefully so that the ball bearing of Rotor does not touch

the circuit board of Stator. Quick insertion without care may cause a damage.

2. Maintain enough distance between Rotors in stock. Even if one is close to another

during carrying and storing, they suddenly attract due to strongly magnetic force.

The contact of Rotors cause cracks and damage of the magnet and weakening

the magnetic force. (Fig. 32)

3. Two halves of Motor housing set are difficult to meet their

matching surfaces.

Therefore, put them on 1R350 to align the four holes

surfaces with Gear box contact portions. And tighten three

4x18 Tapping screws for assembling Motor housing R to

Motor housing L.

Refer to Fig. 34 (for BBC231U and AT-3623) / Fig. 34A (for BBC300L and AT-3630).

Note: 1. Steel ball 5.0 and Compression spring 2 are easy to miss. Therefore, hold them by fingers and remove Indicator

from Main grip L when disassembling.

2. Insert Indicator into Main grip L, and attach Steel ball 5.0 to Indicator.

After above steps, set Compression spring 2 in place.

Fit the protrusions of Link plate into the holders of Grip L.

Fit the protrusion of Switch into the notch of Link plate.

Fit the protrusion of Lock off button into the notch of Link plate. (Fig. 35)

ASSEMBLING

Fig. 32

Fig. 33

Fig. 34

Fig. 35

Fig. 34A

Four holes surfaces of

Motor housing set for

setting Gear box in place

1R350

4x18 Tapping

screw

(3pcs.)

Indicator

Grip L

Grip L

Indicator

Steel ball 5.0

Compression

spring 2

Steel ball 5.0

Holders of Grip L

for Link plate

Notch of Link

plate for Switch

Protrusion of

Switch for

Link plate

Compression

spring 2

Link plate

protrusions

Protrusion of

Lock off button

Notch of Link plate for Lock off button