8

16. Draw attention to the need to use cutters of the

correct shank diameter and which are suitable

for the speed of the tool.

17. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

18. Always use the correct dust mask/respirator for

the material and application you are working

with.

SAVE THESE INSTRUCTIONS.

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

OPERATING INSTRUCTIONS

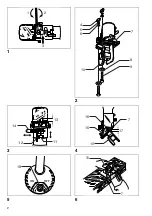

Installing or removing trimmer bit (Fig. 1)

Important:

Always be sure that the tool is switched off and unplugged

before installing or removing the bit.

Insert the bit all the way into the collet cone and tighten

the collet nut securely with the two wrenches. To remove

the bit, follow the installation procedure in reverse.

CAUTION:

• Do not tighten the collet nut without inserting a bit, or

the collet cone will break.

• Use only the wrenches provided with the tool.

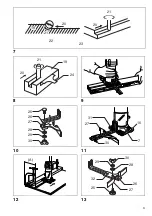

Installing trimmer shoe

(after it has been removed from the tool)

(Fig. 2)

NOTE:

The trimmer shoe is factory installed on the tool.

Use the bolts, wing nuts, spring washers and flat washers

to install the trimmer shoe as shown in

Fig. 2

.

Adjusting bit protrusion (Fig. 3)

To adjust the bit protrusion, loosen the lever and move

the tool base up or down as desired by pressing and

turning the adjusting roller. After adjusting, tighten the

lever firmly to secure the tool base.

Adjusting angle of tool base (Fig. 4)

Loosen the wing bolts and adjust the angle of the tool base

(5° per graduation) to obtain the desired cutting angle.

Adjusting amount of chamfering

To adjust the amount of chamfering, loosen the wing nuts

and adjust the trimmer shoe.

CAUTION:

With the tool unplugged and switch in the “OFF” position,

rotate the collet nut on the tool several times to be sure

that the bit turns freely and does not contact the base or

trimmer shoe in any way.

Switch action (Fig. 5)

CAUTION:

Before plugging in the tool, always be sure that the tool is

switched off.

To start the tool, move the switch lever to the “I” (ON)

position. To stop the tool, move the switch lever to the “0”

(OFF) position.

The tool equipped with electronic function is easy to

operate because of the following features.

Constant speed control

For 3708FC only

Electronic speed control for obtaining constant speed.

Possible to get fine finish, because the rotating speed is

kept constant even under load condition.

Soft start

For 3708FC only

Soft-start feature minimizes start-up shock, and makes

the tool start smoothly.

Lighting up the lamps

For 3708F/3708FC only

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

• Do not look in the light or see the source of light

directly.

To turn on the lamp, start the tool. Then, the lamp lights

up the top of the bit. To turn it off, stop the tool.

NOTE:

Use a dry cloth to wipe the dirt off the lens of lamp. Be

careful not to scratch the lens of lamp, or it may lower the

illumination.

Operation (Fig. 6, 7 & 8)

Turn the tool on without the bit making any contact with

the workpiece and wait until the bit attains full speed.

Then move the tool over the workpiece surface, keeping

the tool base and trimmer shoe flush with the sides of the

workpiece.

(Note)

This tool can be used as a conventional trimmer when

you remove the trimmer shoe.

When doing edge cutting, the workpiece surface should

be on the left side of the bit in the feed direction.

NOTE:

• Moving the tool forward too fast may cause a poor qual-

ity of cut, or damage to the bit or motor. Moving the tool

forward too slowly may burn and mar the cut. The

proper feed rate will depend on the bit size, the kind of

workpiece and depth of cut. Before beginning the cut

on the actual workpiece, it is advisable to make a sam-

ple cut on a piece of scrap lumber. This will show

exactly how the cut will look as well as enable you to

check dimensions.

• When using the trimmer shoe, the straight guide or the

trimmer guide, be sure to keep it on the right side in the

feed direction. This will help to keep it flush with the

side of the workpiece.

CAUTION:

Since excessive cutting may cause overload of the motor

or difficulty in controlling the tool, the depth of cut should

not be more than 3 mm at a pass when cutting grooves.

When you wish to cut grooves more than 3 mm deep, make

several passes with progressively deeper bit settings.