24

360 DVS Series Direct Vent Fireplaces

10006326

Glass Cleaning

It is necessary to periodically clean glass. During start-

up, condensation, which is normal, forms on the inside

of the glass. This condensation causes lint, dust and

other airborne particles to cling to glass surface.

Also initial paint curing may deposit a slight film on the

glass. It is therefore recommended glass be cleaned

two or three times with a non-ammonia based house-

hold cleaner and warm water. The use of fireplace glass

cleaner is recommended within the first few weeks of

operation.

After the initial cleaning process the glass should be

cleaned two or three times during each operating sea-

son depending on the environment in the house.

Clean the glass after the first two weeks of

operation.

Do not clean the glass when hot.

Do not use an abrasive cleaner.

Do not strike or slam the glass.

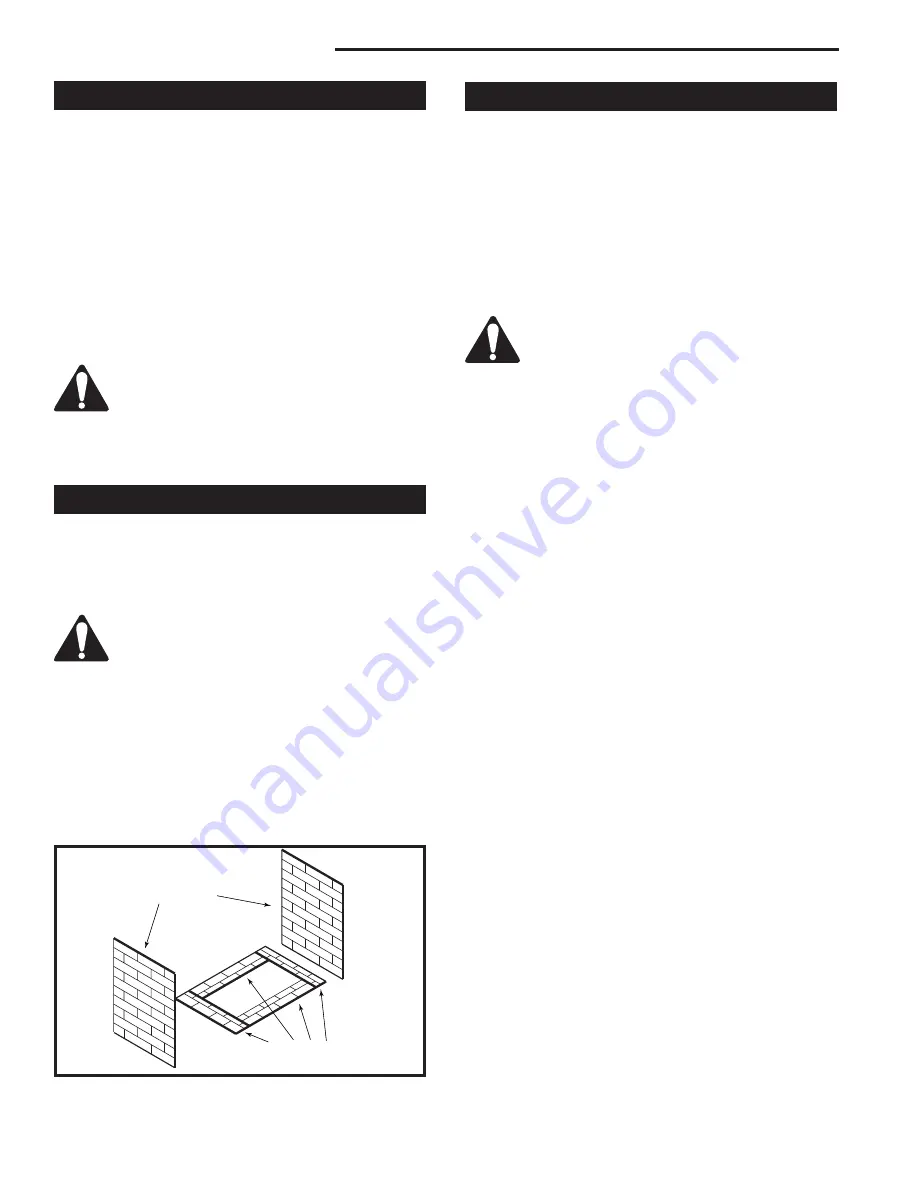

Ceramic Refractory Installation

The vertical refractory panels are installed in the unit

prior to shipment. For assembly procedures, refer to

Figure 39.

1. Unpack the ceramic refractory panels from the car-

ton.

Handle the refractory material carefully, the

panels are fragile.

2. Place the two end floor refractory panels on the base

of the fireplace.

3. Place both side panels along the side of the base.

NOTE:

360DVS2 is the only 360DV unit that is fitted

with two (2) end vertical panels, as shown in Figure

39. 360DVSL and 360DVSR units are each fitted

with one end vertical panel and two side vertical

panel. The 360DVS3 has only one end vertical

panel.

FP1446

Cer_refract_panels-designer

360DVS

Vertical Panels in

Place When Shipped

Floor Panels Placed

During Installation

Fig. 39

Ceramic panel installation.

FP1446

Log Installation

Refer to Figures 40 and 41 for log location and align-

ment.

Because of the log stack design, these instructions can

be followed from either side of the fireplace. To follow

these instructions, identify the logs by the number cast

into the underside.

For correct operation of the fireplace, the logs must be

correctly placed in the sequence described below:

1. Unpack the logs from the shipping carton. The logs

are fragile; handle them carefully.

Handle and dispose of plastic bags in

which logs were shipped in a safe manner.

As with all plastics, they are not toys and

should be kept away from infants.

2. Remove both sides of the window frame assembly

(where applicable).

3. Place the

log rear (B120

) on the grate. The square

hole located on the underside of the log is to be

placed over the center of the grate. The inner end

of the log ensures that the bottom hole is located on

the pin of the support.

4. Place the

log front left (B121)

on the grate. The

square hole located on the underside of the log is to

place over the corner leg of the grate. The inner end

of the log ensures the bottom holes are located on

the pin of the support.

5. Place the

log front right (B122)

. Once more, the

square hole fits over the corner leg of the grate.

The inner end of this log maintains a recess on the

underside, which locates over the knob on the top of

the

log front left (B121)

to secure the inner end in

place.

6. Place the

log rear left (B123)

. The bottom back of

the log rests on the grate. The notch at the back of

the log locates over the knob on the top of the

log

rear (B120)

. The bottom of the log rests on top of

the

log front left (B121)

.

7. Place the

log bottom left (B124)

. The log maintains

a step on the outer end, which rests against the

prong of the grate. The alternate end rests on the

side floor refractory panel.

8. Place the

log rear right (B125)

. The log maintains a

hole on the underside, which rests over the knob on

the top of the

log rear (B120)

. The bottom of the log

rests against the side floor refractory panel, and the

side rests against the last prong of the grate.

9. Place the

log center (B126)

. The log maintains a

hole on the underside, which rests over the knob on

the top of the

log front right (B122)

. The alternate

end rests against the side floor refractory panel and

positions between the two (2) prongs of the grate.