11

54-610 Thermatel Model TD1/TD2 Flow Level Switch

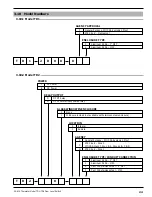

2.6.3 Adjustment Procedure – HIGH FLOW Detection

1. Place Fail-safe in the “HL” position (

).

2. Increase the flow rate to desired alarm point. Allow 3

minutes for the sensor to stabilize.

3. Rotate alarm potentiometer counterclockwise until the red

LED turns on.

4. Rotate alarm potentiometer clockwise until the red LED

goes out.

5. Repeat steps 4 and 5 several times leaving the red LED in

the “on” position.

6. Reduce flow to normal condition, the alarm should reset.

7. Increase flow to the desired alarm point. If the response

time required to detect high flow is too long, rotate alarm

potentiometer counterclockwise

1

⁄

2

turn and test again.

2.6.3.1 Unable to Change Flow Rate

1. Maintain flow rate at normal operating conditions. Allow

3 minutes for the sensor to stabilize.

2. Follow the procedures below for Low Flow Alarm or High

Flow Alarm.

Low Flow Alarm

a. Set fail-safe to “LL” position (

).

b. Rotate alarm potentiometer counterclockwise until the red

LED turns on.

c. Rotate alarm potentiometer clockwise until the red LED

goes out.

d. Repeat steps b and c several times leaving the LED in the

off position. Continue to rotate the potentiometer

1

⁄

2

turn

clockwise. The set point is now just below the present flow

rate. When the flow rate drops below the present flow rate

the red LED will turn on and the relay will de-energize.

High Flow Alarm

a. Set fail-safe to “HL” position (

).

b. Rotate alarm potentiometer counterclockwise until the red

LED turns on.

c. Rotate alarm potentiometer clockwise until the red LED

goes out.

d. Repeat steps b and c several times leaving the LED in the

"off" position. Continue to rotate the potentiometer

1

⁄

2

turn clockwise. The set point is now just higher than the

present flow rate. When the flow rate increases above the

present flow rate the red LED will turn on and the relay

will de-energize.

High Flow Adjustment

(High Level Fail-safe)

Faster alarm or

decrease alarm point

Faster reset or

increase alarm point

Turn

Turn