PROBLEMS AND SOLUTIONS

MAINTENANCE

All models are designed and constructed to require a minimum of maintenance.

In any case always bear in mind the following basic recommendations for a good functioning of

the pump:

- On a weekly basis, check that the tubing joints have not loosened, to avoid any leakage.

- On a monthly basis, check the pump body and keep it clean of any impurities.

- On a weekly basis, check and keep clean the line suction filter.

- On a monthly basis, check that the electric power supply cables are in good condition.

-

NOISE LEVEL

Under normal working conditions the noise emission from all models does not exceed the valve

of 70 db at a distance of 1 meter from the electric pump.

DISPOSING OF CONTAMINATED MATERIALS

In the event of maintenance or demolition of the machine, do not disperse contaminated parts

into the environment.

Refer to local regulations for their proper disposal.

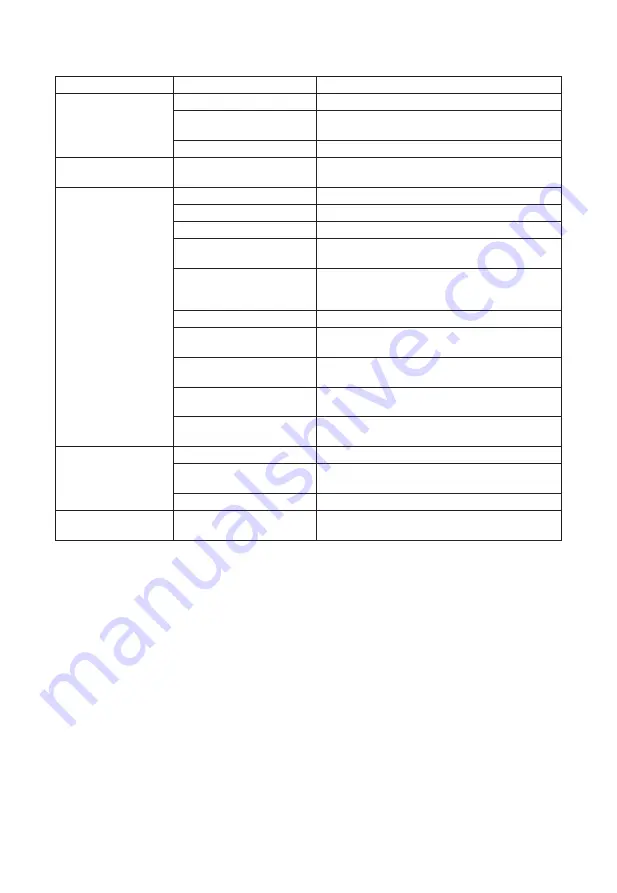

ACCIDENTS

The Motor is not

turning.

The motor turns slowly

when starting.

Low or no flow rate

Increased pump noise

Leakage from the

pump body

CAUSES

Lack of electric power

Rotor Jammed

Motor Problems

Low voltage in the electric

power line

Low level in the suction tank

Foot valve blocked

Filter clogged

Excessive suction pressure

High loss of head in the

delivery circuit (working

with the by-pass open)

By-pass valve blocked

Air entering the pump or the

suction tubing

A narrowing in the suction

tubing

Low rotation speed

The suction tubing is resting

on the bottom of the tank

Cavitation occurring

Irregular functioning of the

by-pass

Air present in the diesel fuel

Seal Damaged

REMEDIES

Check the electrical connecting.

Check for possible damage or obstruction of the

rotating components.

Contact the Service Department

Bring the voltage back within the anticipated limits

Refill the tank

Clean and/or replace the valve

Clean the filter

Lower the pump with respect to the level of the

tank or increase the cross-section of the tubing

Use shorter tubing or of greater diameter

Dismantle the valve, clean and/or replace it.

Check the seals of the Connections

Use tubing suitable for working under suction

pressure

Check the voltage at the pump. Adjust the voltage

and/or use cables of greater cross-section

Raise the tubing

Reduce suction pressure

Dispense fuel until the air is purged from the

by-pass system

Verify the suction connection

Check and replace the seal

E11

Summary of Contents for FTWM120-001

Page 19: ......