© Copyright. Machine Solutions Inc. All Rights Reserved

PM-62319 REV B

18

Equipment User Manual

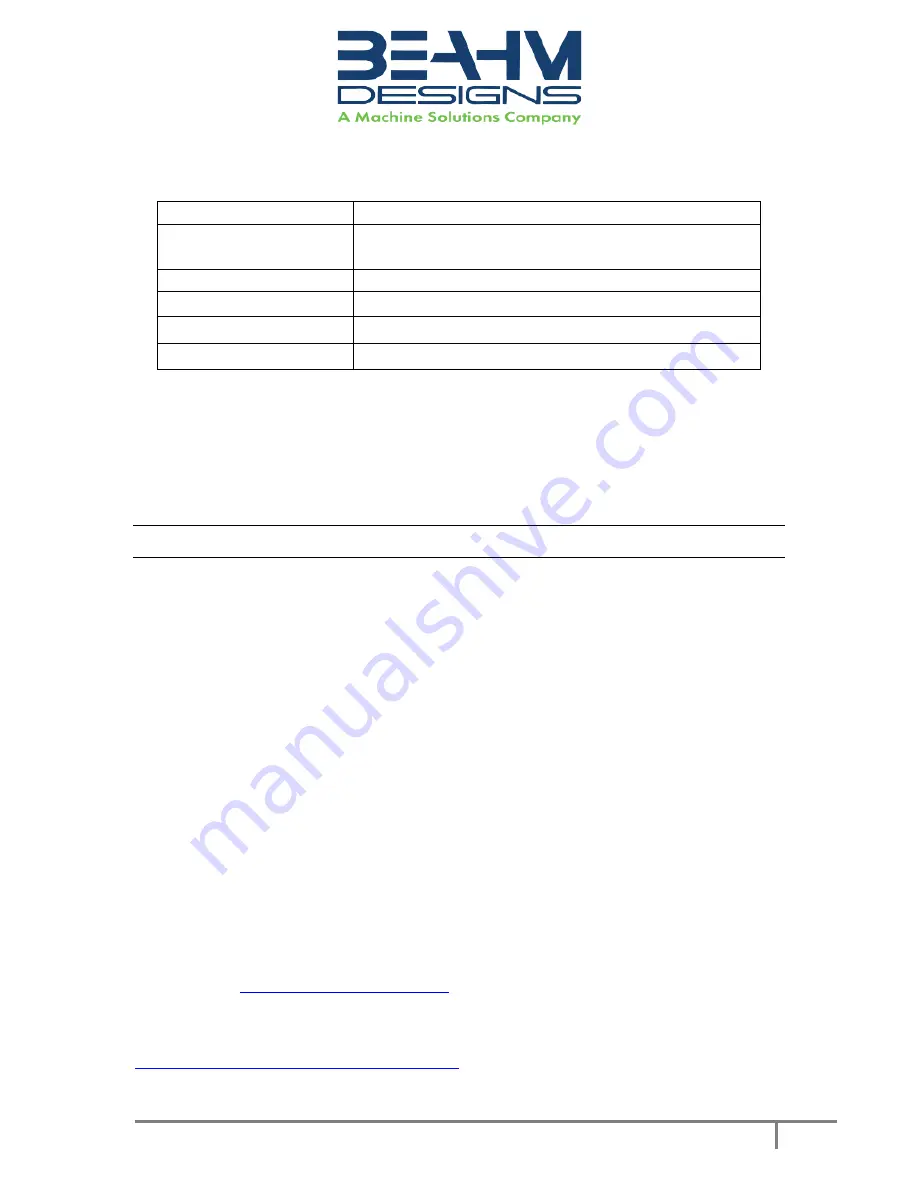

Critical Spare Parts (Contact Beahm Designs for pricing)

P/N

Description

120V

–

1153590-001

220V

–

1157788-001

HEATRER CARTRIDGE

1143133-001

THERMOCOUPLE, K TYPE, 0.125 OD.SLDPRT

1161899-001

TEMPERATURE CONTROLLER

1155195-001

SOLID STATE RELAY

1114668-005

24VDC POWER SUPPLY

Table 1. Critical Spare Parts

Facility Requirements

1. Voltage: 120-240 VAC, 50/60 hz

2. Wattage: 10 amps (500 watts)

3. Compressed Air: 100-125 psi, clean dry compressed air

Warranty

Beahm Designs Inc. (BDI) products are backed by a 1-year warranty on parts and labor.

Warranty is void for any product returned if BDI determines that:

a.

The asserted defect is not present,

b.

The asserted defect is attributed to misuse, improper installation,

alteration (label removal and/or destruction, opening or removing

external covers without authorization by Beahm Designs Inc.),

mishandling and/or mishaps.

c.

The product was not sold to customer as new.

Return Material Authorization

Product may not be returned to Beahm Designs Inc. without first contacting BDI

Aftermarket for a Return Material Authorization (RMA) number. If it is determined that

the Product may be defective, you will be given an RMA number and instructions for

Product return. End Users are required to include a copy of the RMA receipt inside the

return box, in order to receive replacement product under the warranty. All

unauthorized returns i.e., one for which an RMA number has not been issued, will be

returned at the customers expense. To request an RMA, please contact us at

928-556-

3109

or email

For additional information on Beahm Designs, Split Die Thermal Bonder, please visit

Summary of Contents for BEAHM DESIGNS 43-B

Page 1: ...BEAHM DESIGNS BENCH TOP DIE NECKER MODEL 43 B...

Page 9: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 9 Equipment User Manual...

Page 10: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 10 Equipment User Manual...

Page 11: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 11 Equipment User Manual...

Page 12: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 12 Equipment User Manual...

Page 14: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 14 Equipment User Manual...

Page 15: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 15 Equipment User Manual...