R7M-RS4

P. 2 / 7

EM-7803-C Rev.5

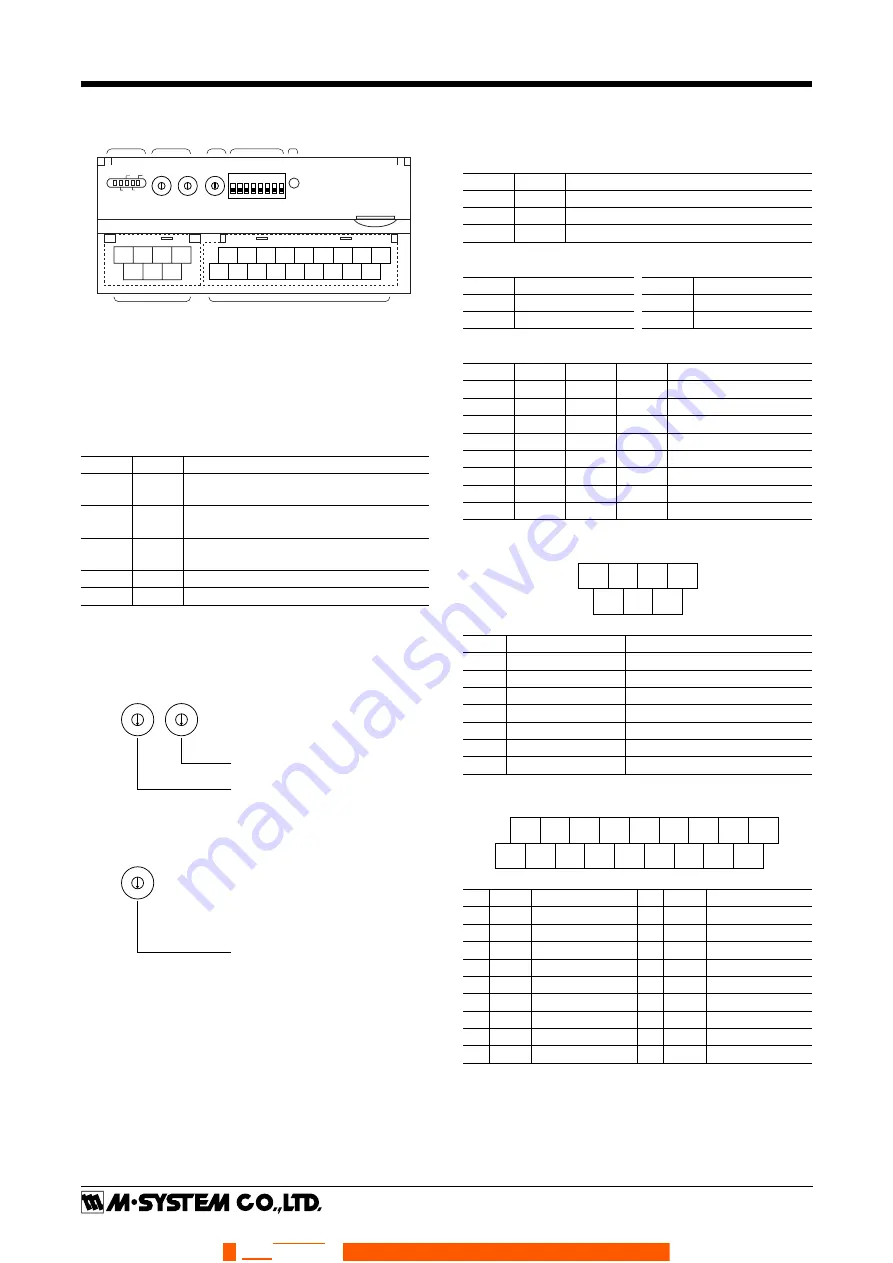

COMPONENT IDENTIFICATION

5

4

3

2 1 0 9

8

7

6

5

4

3

2 1 0 9

8

7

6

5

4

3

2 1 0 9

8

7

6

ERR

RD

RUN

SD

PWR

X10

X1

NODE ADD.

B.RATE

CNFG.

1

2

3

4

5

6

7

8

4

5

6

7

1

2

3

10 11 12 13

2

3

4

1

15 16 17 18

7

8

9

6

14

5

(A) Status Indicator LED

(B) Node Address Setting Rotary SW

(C) Baud Rate Setting Rotary SW

(D) Operating Mode Setting DIP SW (SW1)

(E) PC Configurator Jack

(F) Modbus, Power Supply Terminals

(G) Input Terminals

(A)

(F)

(G)

(B)

(C)

(D)

(E)

■

STATUS INDICATOR LED

ID

COLOR FUNCTION

PWR

Red

Turns on when the internal 5V is supplied

normally.

RUN

Red

Turns on when the data is received nor-

mally.

ERR

Red

Turns on when the received data is abnor-

mal. Blinks when setting is abnormal.

SD

Red

Turns on when the module is transmitting.

RD

Red

Turns on when the module is receiving.

■

NODE ADDRESS

Node Address is selected between 1 and 99 in decimal. The

left switch determines the tenth place digit, while the right

switch does the ones place digit of the address.

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

Node Address Setting (x1)

Factory setting : 00

Node Address Setting (x10)

■

BAUD RATE

Baud Rate is selected with the rotary switch.

5

4

3

2

1

0

9

8

7

6

Baud Rate Setting

0 : 38.4 kbps (factory setting)

1 : 19.2 kbps

2 : 9600 bps

3 : 4800 bps

■

EXTENSION MODULE

Combinations with all extension modules are selectable.

■

OPERATING MODE

(*) Factory setting

•

Extension (SW1-1, 1-2)

SW1-1

SW1-2 EXTENSION

OFF

OFF

No extension (*)

ON

OFF

Discrete input, 8 or 16 points

OFF

ON

Discrete output, 8 or 16 points

• Conversion Rate (SW1-3) • Burnout (SW1-4)

SW1-3 Conversion rate

SW1-4 Burnout

OFF

250 msec. (*)

OFF

Upscale (*)

ON

500 msec.

ON

Downscale

•

RTD Type (SW1-5, 1-6, 1-7, 1-8)

SW1-5

SW1-6

SW1-7

SW1-8 RTD TYPE

OFF

OFF

OFF

OFF

Pt 100 (JIS ’97/IEC) (*)

ON

OFF

OFF

OFF

Pt 100 (JIS ’89)

OFF

ON

OFF

OFF

JPt 100 (JIS ’89)

ON

ON

OFF

OFF

Pt 50 (JIS ’81)

OFF

OFF

ON

OFF

Ni 100

ON

OFF

ON

OFF

Cu 10 (25°C)

OFF

OFF

OFF

ON

Cu 50

ON

ON

ON

ON

PC Configurator setting

■

POWER SUPPLY, MODBUS TERMINAL ASSIGNMENT

4

DA

5

DG

6

+24V

1

DB

2

SLD

3

FG

7

0V

NO.

ID

FUNCTION, NOTES

1

DB

----

2

SLD

Shield

3

FG

FG

4

DA

----

5

DG

----

6

+24V

Power input (24V DC)

7

0V

Power input (0V)

■

INPUT TERMINAL ASSIGNMENT

10

INA0

11

INb0

12

INA1

1

NC

2

INB0

3

NC

13

INb1

4

INB1

14

NC

5

NC

15

INA2

6

NC

16

INb2

7

INB2

17

INA3

8

NC

9

INB3

18

INb3

NO.

ID

FUNCTION

NO.

ID

FUNCTION

1

NC

No connection

10 INA0 RTD 0-A

2

INB0 RTD 0-B

11 INb0 RTD 0-b

3

NC

No connection

12 INA1 RTD 1-A

4

INB1 RTD 1-B

13 INb1 RTD 1-b

5

NC

No connection

14

NC

No connection

6

NC

No connection

15 INA2 RTD 2-A

7

INB2 RTD 2-B

16 INb2 RTD 2-b

8

NC

No connection

17 INA3 RTD 3-A

9

INB3 RTD 3-B

18 INb3 RTD 3-b

056 222 38 18

www.sentronic.com

SENTRONIC

AG