14

Publication: ZTB-080112

M-B Companies, Inc. 11/14/12

iNTRODUcTiON

ADjUSTMENT AND SERvicE

ScRAPER hEighT ADjUSTMENT

The height of the scraper blade (cutting edge) will determine the quality

of snow removal. The scraper blade mounting position is fixed and

cannot be adjusted. The position of the skid shoes is adjusted vertically

to change the scraper blade clearance height.

If the skid shoes are positioned too far down, the scraper blade will not

clear all the snow. If skid shoes are set too high, the scraper blade will

wear and allow the ribbon (auger) to make contact with the ground.

Mismatched skid shoe heights will cause uneaven clearing of snow.

WARNiNg!

When making repairs or

adjustments, the tractor engine

must be Off if the snowblower is

connected.

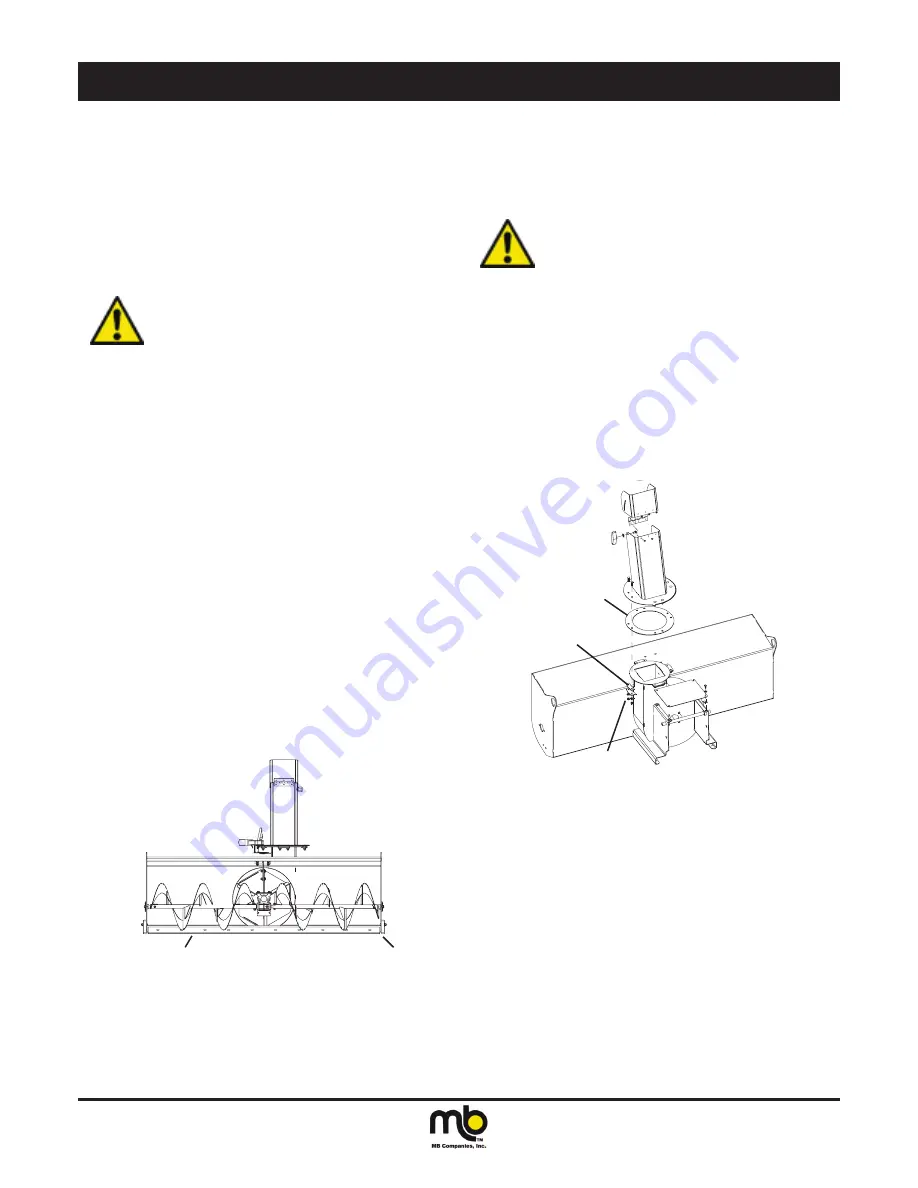

1.

Park the tractor with the mounted snowblower on a hard, flat,

level surface; preferably concrete or asphalt.

2. Raise snowblower high enough to allow placement of shims

listed in step 3.

If using the snowblower on gravel or uneven surfaces, a

minimum gap of 1" (25 mm) is recommended to minimize the

scraping of unwanted debris. This will help avoid running gravel

through the snowblower. Allow 1/8" (3 mm) between scraper

blade and hard, smooth surfaces. Use appropriate shims when

adjusting height.

3. Place shims between scraper blade and hard, smooth ground

surface.

4. Lower snowblower onto ground/shims.

5. Shut off the tractor. Remove key from ignition and apply parking

brake.

6. Loosen the two lock nuts and carriage bolts for mounting each

skid shoe.

7. Push the skid shoes downward to make solid contact with the

ground. Tighten all mounting locknuts and bolts.

8. Remove shims from below scraper blade.

9. With the skid shoes on the ground, check the clearance

between scraper blade and ground surface. The ribbon must not

be in contact with ground.

NOTE:

If the skid shoes are wearing unevenly they can be

switched to the opposite side. When the skid shoes are

worn out they must be replaced.

Place shims between the

ground and the scraper blade.

Skid Shoe

Figure 15

DiSchARgE chUTE gLiDE RiNg

The glide ring provides a sliding surface for the discharge chute

rotation. To clean and lubricate or replace the glide ring, the discharge

chute must be removed.

WARNiNg!

When making repairs or

adjustments on the snowblower,

the tractor engine must be off if the

snowblower is connected.

1. Support the discharge chute. Remove the nuts from all four of

the poly slide hold downs. The poly slides should be removed

and cleaned.

2. Lift the discharge up to remove the glide ring.

3. Clean or replace the glide ring. When reinsalling the glide ring

the bottom side should be lubricated with a spray grease.

4. Place the discharge chute in posiiton. Line up the carriage bolts

with the glide ring and the teeth in the plate with the rotation

drive gear.

5. Place the upper and lower poly slide pieces in place and secure

with a washer and locking nut.

6. Tighten the nuts so the chute rotates smoothly and is not a

loose fit.

Remove Nuts

Glide Ring

Poly Slides

Figure 16

Summary of Contents for ZTB

Page 2: ......