20

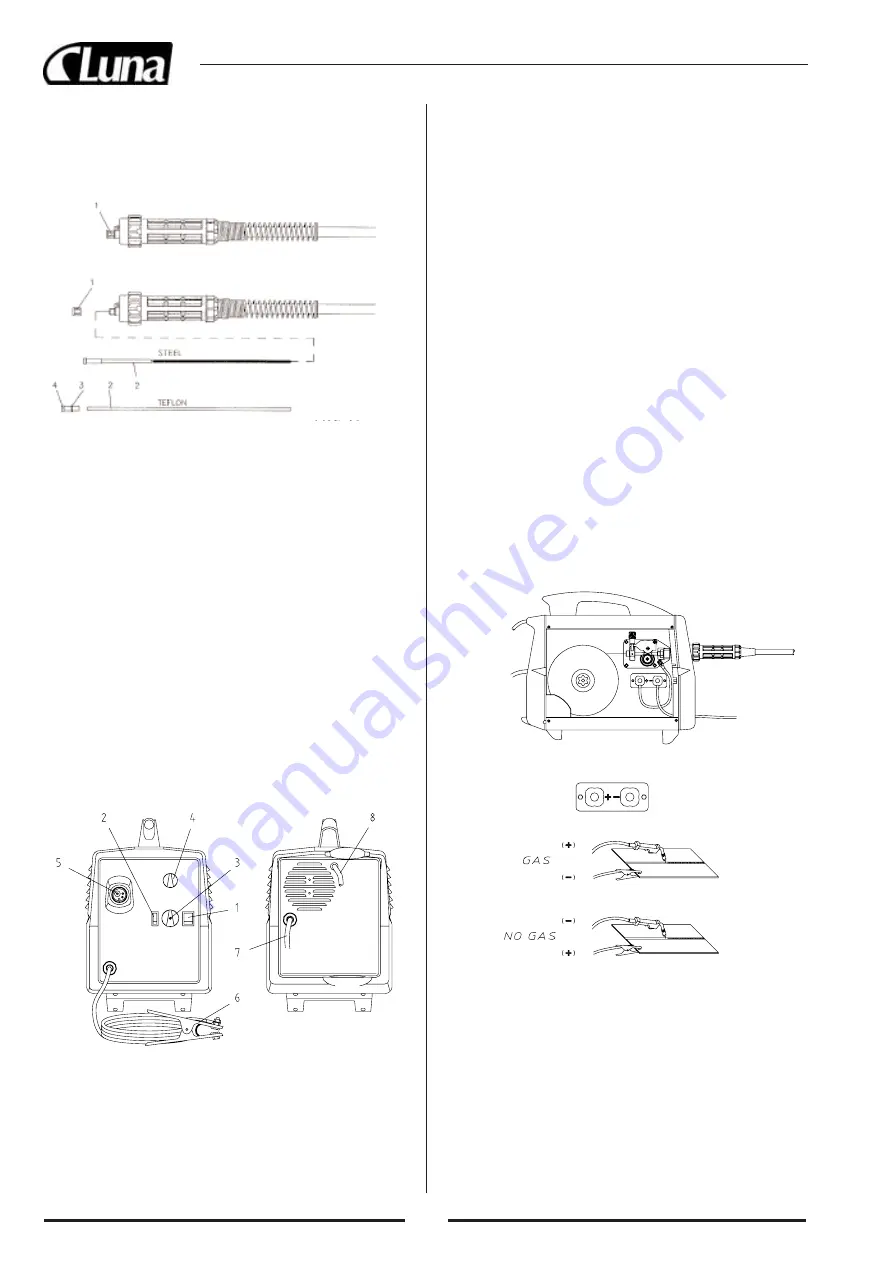

1) Main ON/OFF switch (fig. 6)

This yellow switch functions also as overtemperature pilot lamp; it will

light up if the thermostatic protection will cut off the machine and will

automatically extinguish after the machine has cooled sufficiently.

2) Min/Max switch

3) Voltage selector commutator

It is a 3 position rotary switch. With this switch you can adjust the welding

voltage according to the wire feed speed and wire diameter. The 3 position

rotary switch is completed by a Min/Max switch. Through the different

combinations you can obtain 6 voltage levels.

4) Wire speed adjustment knob

To increase the wire speed, turn the potentiometer clockwise; to decrease

the wire speed, turn it counter-clockwise.

5) Torch connection

6) Ground cable

7) supply cable

8) Gas hose

8.0 MIG WELDING

In MIG welding (Metal Inert Gas) a continuously fed metal electrode is

melted into a welding pool at constant and controlled speed. The wire is

connected to a constant voltage pole while the workpiece is connected to

the other pole. When the wire is fed and touches the workpiece, an electric

arc is produced. The arc melts the wire that is deposited on the workpiece

9.0 GAS WELDING

In order to weld Stainless steel or Aluminium the power source must be

set for gas welding *.

This operation is very simple, you only need the following spare parts

and items (please contact your welding supplier):

1. Wire – All these power sources work with 5Kg-wire spools (wire dia-

meter 0.6mm or 0.8mm).

2. Tip – The tip is correct when it matches with the wire diameter. (Note:

when using aluminium wire of diameter 0.8mm the tip must be

1.0mm)

3. Gas – You can buy disposable gas cylinders from the local distributor

or from a reseller of spare parts, while rechargeable gas cylinders can

be supplied by the local re-seller of spare parts.

4. Gas regulators – You can buy the regulator suited for the gas cylinder

from the local distributor or from a re-seller of spare parts for welding

equipment. Note: As first thing you should decide if you want to use

rechargeable or disposable gas cylinders because this will affect the

choice of the regulator

10.0 WELDING PREPARATION

Fig. 5

motor at variable speed must slide through the liner; when it exits from

the torch neck, release the torch switch, turn off the machine and mount

the contact tip and the nozzle.

6.0 RENEWING THE WIRE LINER

Before performing this procedure, ensure the gas and electrical supplies

are disconnected. (fig. 5).

Euro Connection:

Fig.7

Fig.8

• Disconnect the torch from the machine.

• Place it on a flat surface and carefully remove the brass nut (1) (fig. 5).

• Pull the liner out of the hose.

• Install the new liner and mount the brass nut (1) again.

• In case you are replacing a Teflon wire liner, follow these instructions:

• Install the new liner and take care to insert also the O-ring (3) on the wire

liner collet (4).

• Install the collet on the wire liner and replace the brass nut (1).

• Cut the wire liner close to the brass nut.

WARNING: the length of the new wire liner must be the same of the

liner you have just pulled out of the hose.

• Connect the torch to the machine and install the wire into the feeding

system.

6.1 HOW TO CHOOSE THE WIRE LINER FOR EURO

CONNECTION TORCHES.

Mainly we can have 2 types of wire liners: Steel wire liners and Teflon wire

liners.

• The steel wire liners can be coated or not coated: the coated wire liners

are used for air cooled torches; the wire liners which are not coated are

used for water cooled torches.

• The Teflon wire liners are suggested for the welding of Aluminium, as

they allow a smooth feeding of the wire.

Colour

BLUE

RED

YELLOW

Diameter

Ø 0,6-0,9

Ø 1,0-1,2

Ø 1,2-1,6

7.0 WELDERS CONTROL

1. Connect the welding machine to the 230V 50/60Hz line;

2.

IMPORTANT:

make sure that the polarity is correctly set. For GAS

welding the ground cable must be connected to the negative pole (-),

while the torch must be connected to the positive pole (+) (fig. 7).

3. Connect the ground clamp to the workpiece and make sure that the con-

tact is good;

4. Make sure that the wire-feeding roll is correctly positioned (groove mat-

ching the wire diameter). In order to change the groove loosen the knob

that locks the roll. Note that each roll has two grooves one marked by

0,6 mm and the other marked by 0,8 mm. Turn the roll and fix it again

with the screw;

5. Open the gas using the pressure regulator and adjust the flow rate.

(NOTE: The gas flow may need adjustments in order to obtain a better

welding, this depends on the type and thickness of the metal used, any-

way the gas flow should be maintained as low as possible).

Summary of Contents for WM 1605 F

Page 1: ...20421 0090 Gas no gas MIG welding units Svets med gas utan gas WM 1605 F...

Page 45: ...44 1 7 2 0 2 1 0 40 C 300 2 2 2 3 1 230 1 7 S E L 3 0 2 3 1 2 2 A 3 B 3 2 EURO 3 4 0 8...

Page 49: ...48 17 0...

Page 55: ...54...

Page 56: ...55...

Page 57: ...56...