57

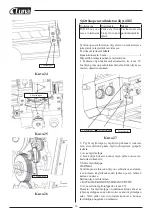

If the carriage starts moving, immediately push the

STOP button and disengage the carriage feed lever,

then restart the lathe.

10. Allow the lathe to run for at least two full minutes

to make sure it is running satisfactorily and the chuck

is turning clockwise.

11. Press the “Stop”.

12. After the chuck has come to a complete stop, Press

the “Forward”.

13. Allow the lathe to run for at least two full minutes

to make sure it is running satisfactorily and the chuck

is turning counter clockwise.

14. Press the “Stop”.

15. After the lathe has come to a complete stop, en-

gage the carriage hand wheel, rotate the hand wheel to

center the carriage on the bed, then disengage the hand

wheel.

16. Engage the automatic carriage feed lever.

17. Turn the lathe ON.

18. Verify that the carriage moves along the bed, then

press the emergency stop button to turn the lathe OFF.

19. Disengage the feed lever.

SECTION 4: OPERATE

General

The Model C8 will perform many types of operations

that are beyond the scope of this manual. Many of the-

se operations can be dangerous or deadly if performed

incorrectly.

The instructions in this section are written with the

understanding that the operator has the necessary

knowledge and skills to operate this machine. If at any

time you are experiencing difficulties performing any

operation, stop using the machine!

If you are an inexperienced operator, we strongly re-

commend that you read books, trade articles, or seek

training from an experienced lathe operator before

performing any unfamiliar operations. Above all, your

safety should come first!

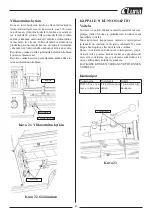

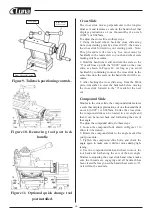

Controls

To get the most out of your machine, please take the

time to familiarize yourself with the various controls

and components shown in the Figures 3.

Note: The ”Milling/Drilling” option at the selector

switch is intended for the optional installation of a

milling attachment which is sold separately. Please

contact your authorized dealer for more information.

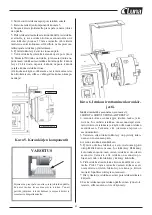

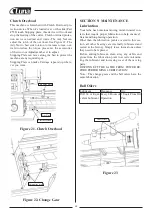

Figure 4. Compound Slide

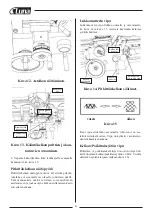

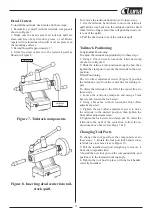

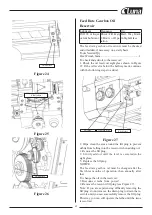

Removing/Installing Chuck or

Faceplate

The C8 spindle nose mounting system uses a circular

lock plate with slotted holes that are oversized at one

end (keyholes). When the lock plate is rotated counter-

clockwise (as facing the chuck), the studs with moun-

ting nuts can pass through the spindle nose. When

the lock plate is rotated toward the back of the lathe,

the oversized holes narrow to the size of the studs, al-

lowing the mounting nuts to be tightened against the

back of the lock plate, thus, securing the chuck or fa-

ceplate.

To remove a chuck or faceplate from the lathe spindle

nose, do these steps:

WARNING

Read and understand this entire instruction manual

before using this machine. Serious personal injury

may occur if safety and operational information

is not understood and followed. Do not risk your

safety by not reading

Compound

slide

Compound

cap screws

Compound

bolts

Compound

handwheel

Summary of Contents for 21149-0107

Page 1: ...Metal lathe ML1130 21149 0107...

Page 2: ......

Page 5: ...4...

Page 100: ...99 30 pav Past mos prispaud iamosios plok tel s var tai...

Page 132: ...131 Rys 30 ruby regulacyjne listew kli nowych sa wzd u nych...

Page 148: ...147 WIRING DIAGRAM 28 FRAM T BAK T START STOPP...

Page 149: ...148 EXPLOSION DIAGRAM...

Page 150: ...149...

Page 151: ...150...

Page 152: ...151...

Page 153: ...152...

Page 154: ...153...

Page 155: ...154...

Page 156: ...155...

Page 157: ...156...

Page 165: ......

Page 166: ......

Page 167: ......