14

In order to ensure the proper, ecological and fuel–efficient functioning of Bio-max Plus

boilers, it is recommended to use pellet fuel satisfying the requirements of standard PN–EN

ISO 17225–2:2014–07.

Certified fuels from reliable sources are recommended. The fuels used should be of an

appropriately low humidity and have a low content of volatile substances. Minimum fuel

quality requirements have been presented in the following table.

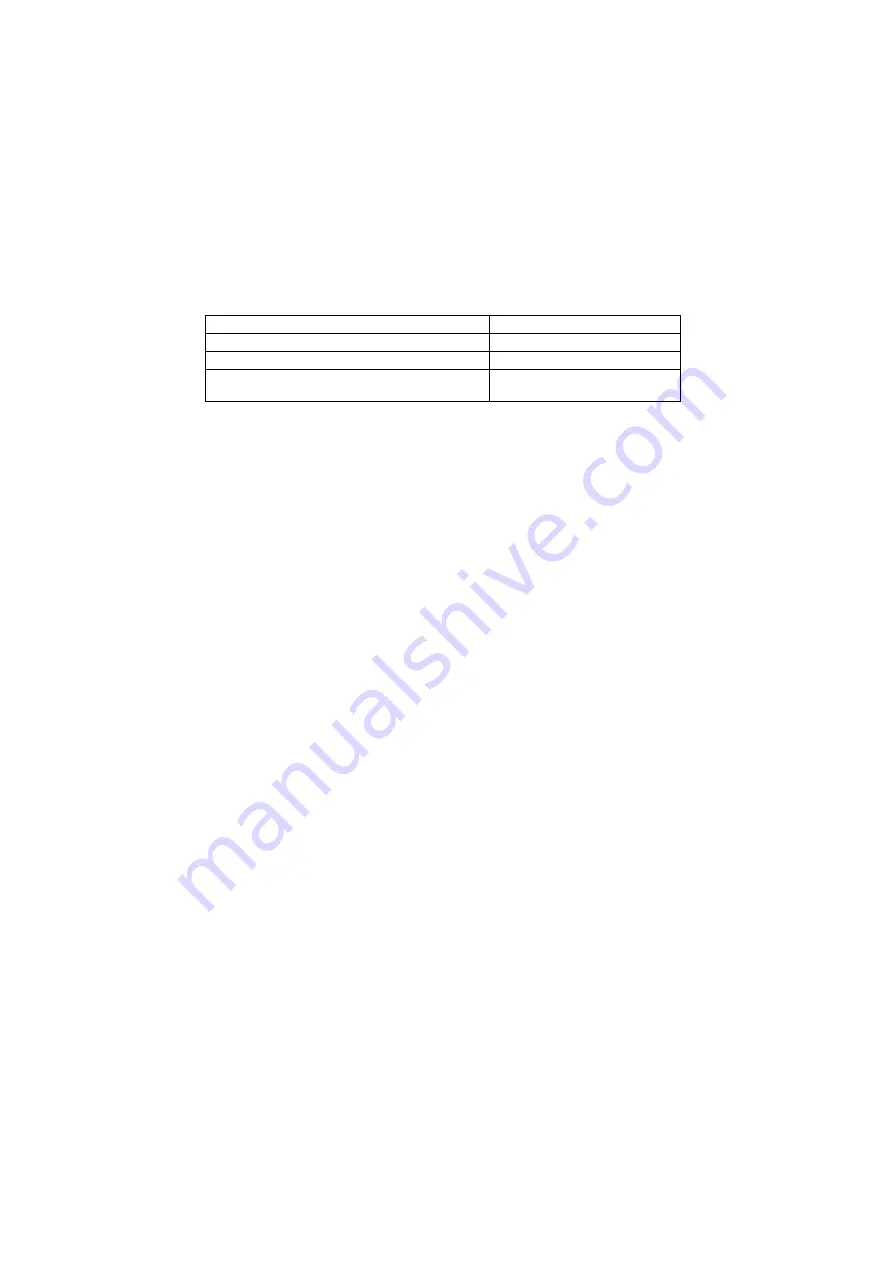

Table No. 3. Minimum fuel quality requirements

Humidity content (in working condition)

≤

12%

Ash content (in working condition)

≤

0.5%

Calorific value

> 17 MJ/kg

Fuel class

C1 according to EN 303-

5:2012

When adding fuel to the tank it is necessary to pay particular attention to mechanical

contaminants (e.g. stones), which could damage the ancillary devices of the boiler (the

burner, feeding mechanisms, automatic ash removal system) and lead to failures for which

the equipment manufacturer shall not be held liable.

4.5. Connection to the central heating water system

Bio-max Plus boilers are factory–fitted with externally threaded stub connectors: a

supply stub connector, a return stub connector, a drainage stub connector and a safety stub

connector (the diameters of stub connectors for various boiler power ratings have been given

in

Table No. 1

). These stub connectors and their corresponding joints are used to connect

the boiler to the central heating system in the appropriate manner (so as not to mix up

“supply” with “return”, for example).

Connections must be made in accordance with the design and currently valid regulations, as

appropriate for the specific system type (i.e. open or closed).

−

Before connecting the boiler, it is necessary to thoroughly clean the system of all

possible contaminants (dirt, rust, etc.).

−

Do not use any magnetisers in the system.

−

Cut–off valves should be installed between the boiler and the central heating

system in order to enable dismantling of the boiler without it being necessary to

purge the whole system of water.

−

In order to protect the boiler against excessively low heating water temperatures

at the heating system return (below 45°C), which could lead to its premature

corrosion, it is required to install a three–way or four–way mixing valve and/or a

boiler feed pump.

−

Ensuring proper circulation in the central heating system will make it possible to

achieve a difference in temperature between supply and return of less than or

equal to 15°C.

−

Water filters should be installed at the heating water return from the central

heating system.

−

Boilers with a power rating in excess of 100 kW must be fitted with a parametric

water level sensor. Depending on the type of sensor, this should be installed on

the boiler in accordance with the attached instruction manual.

Summary of Contents for BIO-MAX PLUS

Page 8: ...8 Figure No 2 Component elements of the boiler Figure No 2 Component elements of the boiler...

Page 9: ...9...

Page 10: ...10 3 2 Technical parameters Figure No 3 Boiler installation dimensions...

Page 16: ...16 Figure No 7 Wiring diagram ecoMAX860P Standard and ecoMAX860P Touch...

Page 29: ...29...