DP13-580B 09

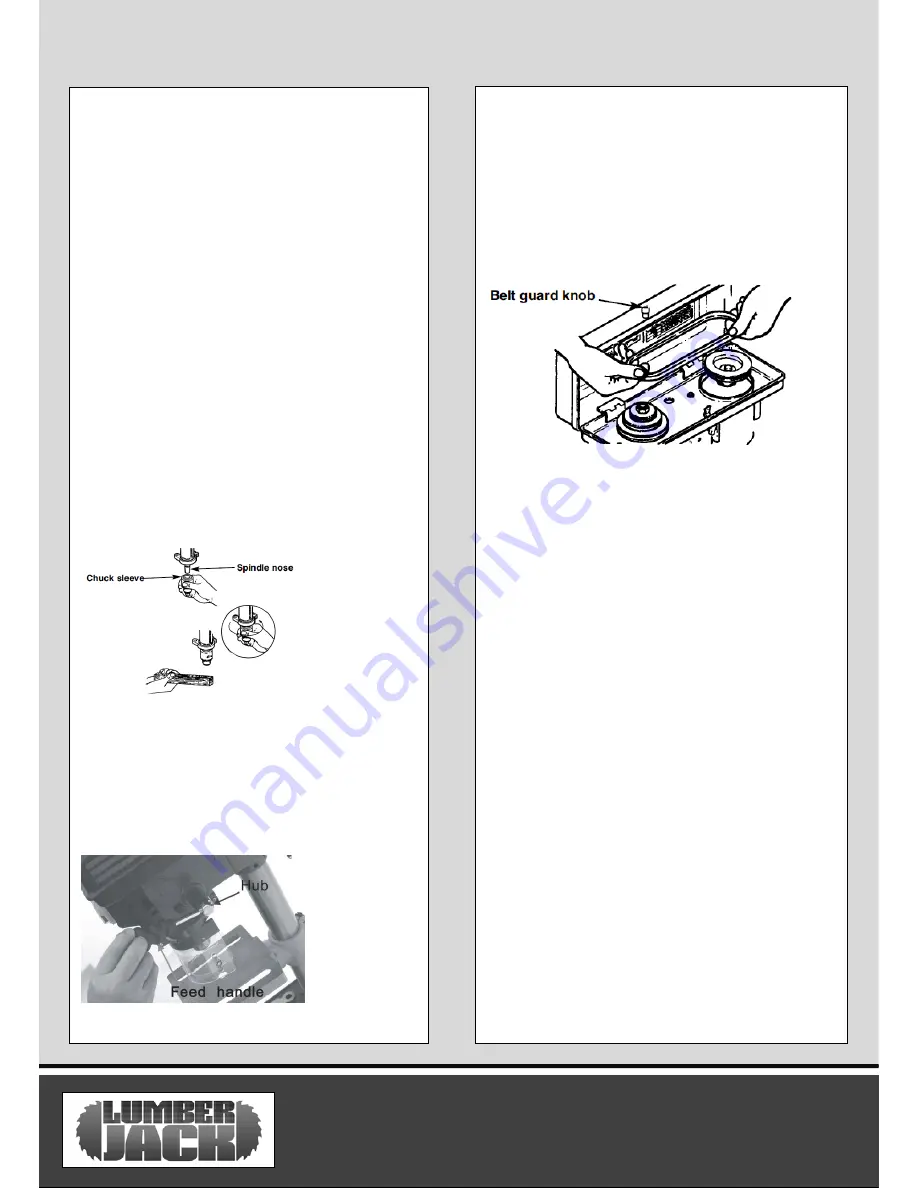

Installation the chuck & arbor

1. Locate the chuck in the box of parts.

2. Tighten Philip’s head screws of the chuck

guard to quill shaft.

3. Clean out the tapered hole in the chuck, also

clean the spindle nose with a clean cloth. Make

sure there are no foreign particles sticking to the

surfaces. The slightest piece of dirt on the

spindle nose or the chuck will prevent the chuck

from seating properly. This will cause the drill to

“wobble” .

NOTE:

If the tapered hole in the chuck is

extremely dirty, use a cleaning solvent on a clean

cloth.

4. Push the chuck up on the spindle nose as far

as it will go.

5. Turn the chuck sleeve clockwise and open the

chuck jaws completely.

6. Lightly tap the nose of the chuck with a piece

of wood to insure the proper seating of the

chuck on the spindle.

Installation the feed handles

1. Locate the three feed handles among the

loose parts.

2. Screw the feed handle tightly into the

threaded holes in the hub.

Installing the belt guard knob

1. To attach the belt guard knob, use the knob and

a pan head screw from the loose parts bag. Insert

the pan head screw into the belt guard and screw

knob. Tighten.

WARNING! :

To

avoid possible injury, keep the

guard in place and in proper working order while

operating.

Tensioning the belt

NOTE: The drill press is shipped with the belt installed,

but it should be properly tensioned before use.

1. Lift the guard from the right side and keep it

opened.

2.

Release the belt tension lock handle located on

the right side of the drill press head. Pull the right

side of the motor towards the front to relieve the

spring tension of the belt. Tighten the belt tension

lock handle.

3. Choose the desired speed for your drilling

operation, and move the belt to the indicated

position. Refer to the chart on the inside of the

belt guard.

4. Loosen the belt tension lock handle and move

the right side of the motor backwards to apply

tension to the belt.

5. Tighten the belt tension lock handle.

NOTE: The belt should deflect approximately 1/2”

by applying finger pressure at the mid-point of the

belt between the pulleys.

6. Close the belt guard.

7. If the belt slips while drilling, readjust the belt

tension.

ASSEMBLY INSTRUCTIONS

Summary of Contents for DP13-580B

Page 21: ...DP13 580B 19 Parts Diagram...

Page 22: ...DP13 580B 20 Parts Diagram...