(8) Technically maximum permissible mass

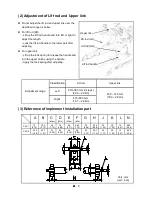

When working with front loader or rear heavy loaded attachments installed to the 3-point linkage,

install ballast weights on the counter-part axle to maintain the front and rear weight balance of the

tractor. If not, front or rear axle can be strained by the overloaded weight.

When working with the front loader, place the attached rear weight to the highest position and turn

the down speed control knob to the “lock” position.

All models

Remarks

Technically total maximum

permissible mass

4500kg (9921 lb)

without consideration of the load

capacity of the tires

Front axle (*)

2000kg (4409 lb)

Rear axle

2500kg (5512 lb)

Rear axle

2500kg (5512 lb)

▶

Maximum permissible mass is measured with only the front or rear wheels on the

scales inclusive of ballasts and with mounted equipments in the raised position.

▶

Do not exceed the maximum permissible mass above. Overloaded condition may

invalidate the warranty and may exceed the load rating of the tires.

▶

If the load capacity of the tire is lower than maximum permissible mass of the front

axle, the maximum load on the front axle meets the load capacity of the tire.

(

See page 4-15

)

▶

DO NOT change the setting pressure of the relief valve arbitrarily to increase the

lift capacity of the front loader or 3-point linkage. It can cause fatal damage to the

Caution

* includes front mounted equipment or loader in the raised position but without load in the bucket.

Restrict operation

: In case of driving speed does not exceed 8km/h (5 mph) and standard

front/rear wheel track (

See next page

), Intermittent maximum permissible load of the front axle can

be ;

3200kg (7055 lb) for all models - without consideration of the load capacity of the tires.

4

4

4

4

- 13

hydraulic system and front axle.