2

www.longer3d.com [email protected]

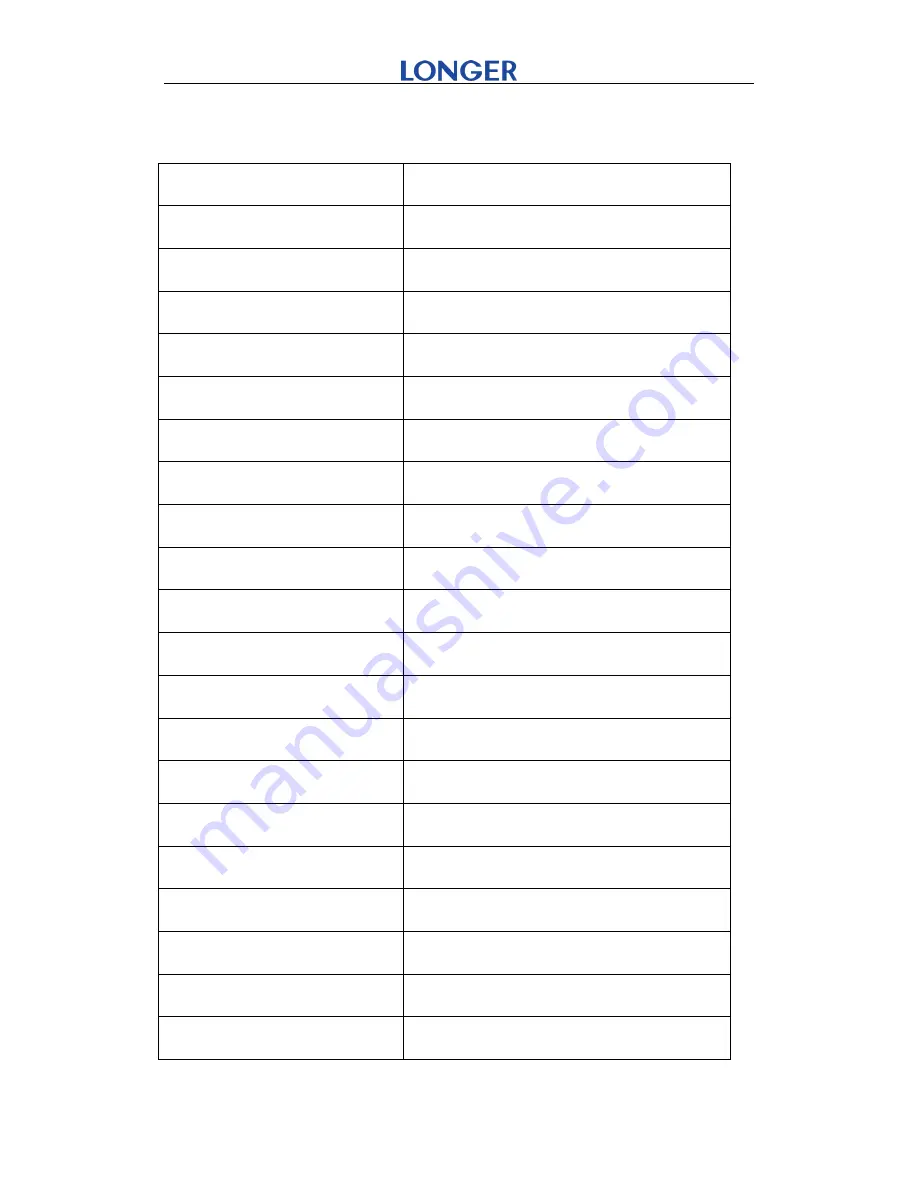

2. Specifications

Equipment Model

Orange120

Printing Technology

LCD stereolithography

Build Size

120

68

150 mm

Layer Thickness

0.02-0.10 mm

LCD Resolution

2560

1440 pixel, 47.25 μm

Z axis Resolution

0.625 μm

Build Speed

30 mm/h

Material

Photopolymer Resin

Light Source

UV LED 405 nm

Software

IFORMER

Operation System

Windows 7/8/10, 64-bit

Connectivity

Ethernet, Wifi

Format

STL

Screen

2.8 inch touch screen

Dimension

Φ220

375 mm

Net Weight

6.0 kg

Package Dimension

315

315

500 mm

Gross Weight

9.0kg

Power Requirement

100-240V AC, 50/60Hz

Working Power

72 W

Operation Environment

15-30℃, moisture 20%-70%