User Manual

CBX-1 / CBX-2

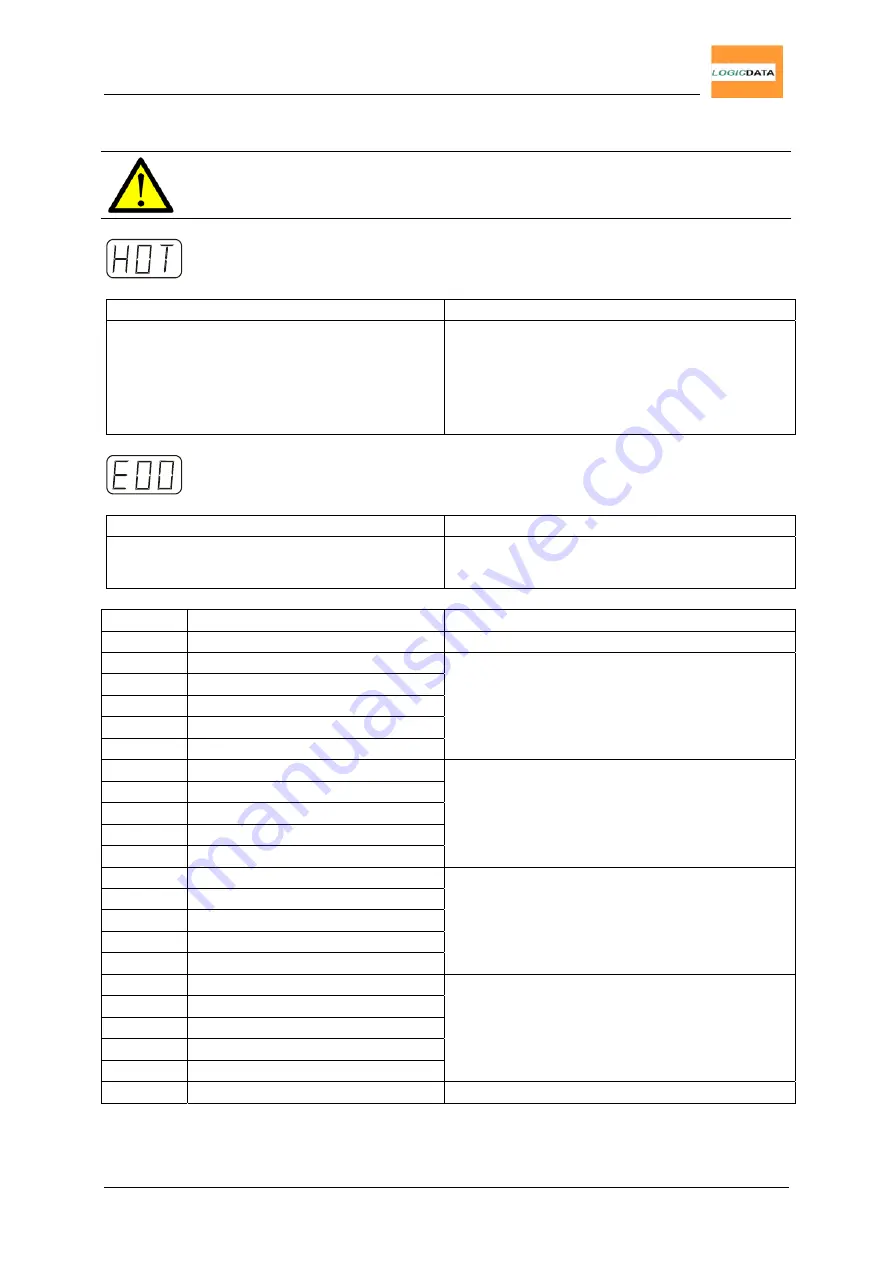

6.2 Displayed Error Messages

Note:

Error messages will only be displayed on handsets with a

display!

The display reads

HOT

.

Cause Solution

The CBX control box is equipped with

duty cycle monitoring. If the predefined

on-time is exceeded, this protection

mechanism gets activated (refer to

chapter 4.3.5).

Wait until the control box has cooled

down and the displyed

HOT

goes out.

Then, the control box is ready for use

again.

The display reads

E

+ a error code.

Cause Solution

An internal error occured.

Proceed according to the following error

list:

Code Description

Solution

00 No

error

01

Relay of motor 1 is stuck

02

Relay of motor 2 is stuck

03

Relay of motor 3 is stuck

04

Relay of motor 4 is stuck

05

Relay of motor 5 is stuck

Unplug the control box. Contact our

customer service.

06

Mosfet of motor 1 defective

07

Mosfet of motor 2 defective

08

Mosfet of motor 3 defective

09

Mosfet of motor 4 defective

10

Mosfet of motor 5 defective

Unplug the control box. Contact our

customer service.

11

Motor 1 socket shorted

12

Motor 2 socket shorted

13

Motor 3 socket shorted

14

Motor 4 socket shorted

15

Motor 5 socket shorted

Unplug the control box.

Eliminate the external short-circuit.

Put the control box into operation again.

16

Motor 1 socket plug detection

17

Motor 2 socket plug detection

18

Motor 3 socket plug detection

19

Motor 4 socket plug detection

20

Motor 5 socket plug detection

Connect a motor to the corresponding

motor socket.

21

Oscillator defective

Contact our customer service.

Page 25/29