Installation & Operation Manual

8

Maintenance

(continued)

63

Check burner flame

Visually check main burner flames at each start-up after long

shutdown periods or at least every six months. A burner

viewport is located on the burner mounting flange.

Perform start-up and checks

Start appliance and perform checks and tests specified in

Section

6 - Start-up

of the Copper-fin

2

Installation and Operation

Manual.

The area around the burner viewport is hot

and direct contact could result in burns.

⚠

WARNING

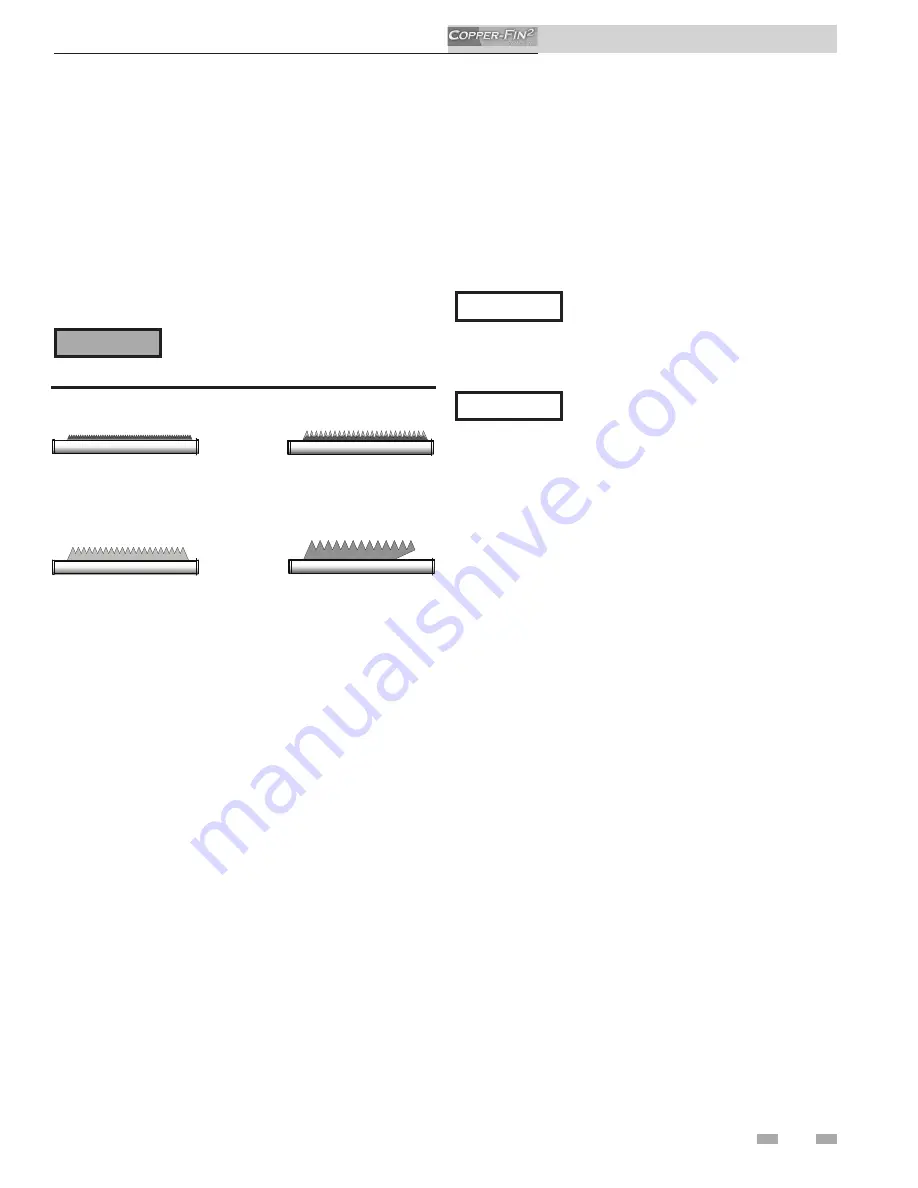

Figure 8-1_

Flame Pattern Illustration

Normal Flame:

A normal flame at 100% of burner input is blue,

with slight yellow tips, a well defined flame and no flame lifting.

Yellow Tip:

Yellow tipping can be caused by blockage or partial

obstruction of air flow to the burner.

Yellow Flames:

Yellow flames can be caused by blockage of

primary air flow to the burner or excessive gas input. This

condition MUST be corrected immediately.

Lifting Flames:

Lifting flames can be caused by over firing the

burner, excessive primary air or high draft.

If improper flame is observed, examine the venting system,

ensure proper gas supply and adequate supply of combustion

and ventilation air.

Check flue gas passageways

Any sign of soot around the inner jacket, outer jacket, flue

pipe connections, burner or in the areas between the fins on

the copper heat exchanger indicates a need for cleaning. The

following cleaning procedure must only be performed by a

qualified serviceman or installer. Proper service is required to

maintain safe operation. Properly installed and adjusted units

seldom need flue cleaning.

All gaskets/sealants on disassembled

components or jacket panels must be

replaced with new gaskets/sealants on

reassembly. Gasket and sealant kits are

available from your distributor.

NOTICE

⚠

CAUTION

When a Category IV vent system is

disconnected for any reason, the flue must

be reassembled and resealed according to the

vent manufacturer’s instructions.

Inspect and clean burner

1. Turn off main power to unit.

2. Turn off main manual gas shutoff to unit.

3. Remove the front outer jacket panels.

4. Disconnect manifold from gas train using union(s) just

below each gas valve(s).

5. Remove mounting screws from manifold mounting

brackets. Pull the manifold/orifice assembly away from

burners. Repeat for each manifold assembly.

6. Remove two mounting screws from burner and slide

burner out toward front of unit. Use caution to prevent

damage to burners, refractory, hot surface igniter or wiring.

7. Remove soot from burners with a stiff bristle brush.

Dirt may be removed from burner ports by rinsing the

burner thoroughly with water. Drain and dry burners

before re-installing. Damaged burners must be replaced.

NORMAL

YELLOW FLAME

FLAME LIFT

YELLOW TIP

When installed in a dusty and dirty location, the burners may

require cleaning on a 3 to 6 month schedule or as needed,

based on severity of contamination. Contaminants can be

drawn in with the combustion air. Non combustible particulate

matter such as dust, dirt, concrete dust or dry wall dust can

block burner ports and cause non-warrantable failure. The

standard inlet air filter will help eliminate dust and dirt from

entering the unit. Use extreme care when operating a unit for

temporary heat during new construction. The burners could

require a thorough cleaning before the unit is placed in service.