Installation & Operation Manual

46

5

Electrical connections

ALARM

S

T

A

G

IN

G

C

A

S

C

A

D

E

M

O

D

B

U

S

CN3

CN2

RUN-TIME

CONTACTS

OPEN

CLOSE

COM

S1

S2

S2

S3

S3

S4

S4

LOUVER

RELAY COIL

LOUVER

PROVING SW

CONTACTS

S1

AQUASTAT

TANK

TANK

SENSOR

SHIELD

A

B

SHIELD

+ 0-10V

- BMS IN

+ 0-10V

- RATE OUT

SHIELD

A

B

SHIELD

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

3

-W

A

Y

V

A

L

V

E

B

TO MONITORING DEVICE

OUTDOOR

SENSOR

SYS SUPPLY

SYS RETURN

+ 0-10V SYS

SENSOR

SENSOR

- PUMP IN

CN2

TO MONITORING DEVICE

THREE WAY

VALVE

LOUVER

PROVING

SWITCH

DHW TANK

THERMOSTAT

LINE

TO LOUVER

10K-TANK

SENSOR

A

B

A

FROM

PREVIOUS

HEATER

TO NEXT

HEATER

EXTERNAL

SEQUENCER/

BUILDING

AUTOMATIC

CONTROL

SYSTEM SUPPLY

SENSOR

SYSTEM RETURN

SENSOR

OUTDOOR

AIR SENSOR

(BOILER ONLY)

PUMP SPEED

INPUT

0-10VDC

COMMON

S1

S2

S3

S4

EXTERNAL

STAGING

SEQUENCER

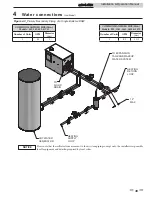

Figure 5-4_Low Voltage Field Wiring Connections

Wiring of the cascade

When wiring the heaters for Cascade operation, select one

heater as the Leader. The remaining heaters will be designated

as Members. See page 50 Configuration of the Cascade for a

detailed explanation of this procedure.

On boilers, connect the system supply sensor and outdoor air

sensor (if used) to the Leader boiler. The location of the system

supply sensor should be downstream of the boiler connections

in the main system loop (FIG.’s 4-3 and 4-6). The system supply

sensor should be wired to the low voltage connection board at

the terminals marked for the system supply sensor (see FIG.

5-4). The Leader control will use the water temperature at the

system supply sensor to control the operation of the Cascade.

If outdoor air reset is desired, the outdoor air sensor should

be wired to the low voltage connection board at the terminals

marked for the outdoor air sensor (FIG. 5-4). If the outdoor

air sensor is connected, the Leader control will calculate the

water temperature set point based on the programmed reset

curve parameters. If the outdoor air sensor is not connected, the

Leader control will maintain the space heating (SH) set point

that is programmed into the control.

If a Thermostat, Zone Control enable output, or Building

Management System enable output are available, it should be

wired to the low voltage connection board on the Leader boiler

at the Staging S1 terminals. If the boilers are to run continuously,

leave the jumper wire between these terminals. This will initiate

a call for heat on the Cascade. Also, leave the jumpers on the

Staging S1 terminals of all the Member heaters. This will allow

them to run independently should the Leader heater fail.

On water heaters, connect the tank thermostat or BMS enable

output to the low voltage connection board on the Leader

heater, at the terminals marked for the tank Aquastat. If a tank

sensor is used, connect this sensor to the low voltage connection

board on the Leader heater, at the terminals marked for the tank

sensor.

Communication between the Leader heater and the Member

heaters is accomplished by using shielded, 2-wire twisted pair

communication cable. Connect one of the twisted pair wires to

terminal A on each of the low voltage connection boards, and

the other wire of the twisted pair to terminal B on each of the

low voltage connection boards. Connect the shield wire to the

shield ground terminal on all of the heaters. If more than two

heaters are on the Cascade, daisy chain the wiring from the

Cascade terminals on the second heater to the Cascade terminals

on the third heater, then from the third to the forth, and so

on. The connections can be made in any order, regardless of

the addresses of the heaters. Try to keep each cable as short as

possible.