The Twist’R Plus (Model RSX4000) Vehicular Gate Operator will

provide convenience and assurance to the ultimate users for many

years. It is ruggedly built of the finest materials and has been

thoroughly inspected and tested at the factory. It has many features that

will aid in the installation and testing of the complete gate system. The

RSX4000 has been designed and built to comply with the UL325

Standard For Safety, Fourth Edition, revised March 1, 2000 as

established by Underwriters Laboratory Inc.

The RSX4000 Vehicular Swing Gate Operator is designated a Class

I Vehicular Swing Gate Operator

, and is intended to operate a

vehicular swing gate installed on a residential home, maximum of four

single families in the dwelling, or a garage or parking area associated

with that home, or a similar location with respect to the cycle usage (see

below). Gate operators are also manufactured for the three other Class

designations (as defined by UL325); Class II (high cycle usage

commercial location or multi-family home); Class III (Industrial

location not intended to service the general public); and Class IV

(secure or restricted access locations, ie. airports and prisons). The

RSX4000 operator cycle usage is rated at a maximum of 10 cycles per

hour, 50 cycles maximum per day.

Because the RSX4000 (as well as gate operators sold by other

manufacturers) is designed to start and move gates weighing as much as

300 pounds and 16 feet in length. As such, the RSX4000 is capable of

producing high levels of force. It is important in the design of the total

gate system that designers, installers and users be aware of the hazards

that may be associated with the

IMPROPER

design, installation and

use of Vehicular Gate systems and Gate Operators.

The gate operator is only one part of a complete automatic gate

operating system. As each location and usage is different, a properly

designed system will include all applicable safety enhancement devices.

As the designer and installer

of the

GATE SYSTEM

, you must

advise the purchaser on the proper use of the gate system. You also

have the primary responsibility of insuring that

ALL

possible

operational hazards have been considered and eliminated.

The RSX4000 CGA2K™ technology provides several features that

can help reduce the hazards of your gate system.

Built-In Adjustable Torque Limiting Drive System

The RSX4000 is provided with a adjustable torque limiting drive

system that may be adjusted to “slip” when an obstruction is

encountered. This system, however, must not be considered as the

primary obstruction sensing system. Consider all available options

(electric leading edges, photoelectric sensors, protective screen mesh,

etc.) to eliminate hazards in your gate system design.

The torque limiting drive system also serves to protect the mechanical

components of the operator.

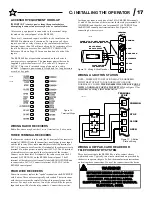

The torque limiting drive setting is an adjustable setting that must be

determined at the time of installation. This setting must be tested

periodically to ensure proper operation. The more freely the gate will

move the more sensitive the setting can be made. See Page 17.

ADVISE THE PURCHASER TO CHECK THE SENSITIVITY OF

THE GATE OPERATION PERIODICALLY AND THEN LOG THE

DATE TESTED IN THE TABLE on page 2. (See Figure 1)

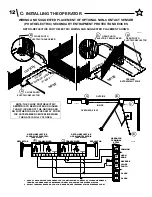

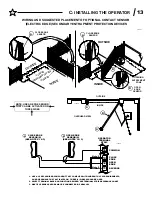

Connections for External Entrapment Prevention Sensors

Because all gate system installations are different, the RSX4000 control

panel provides independent connections for Open and Close contact

(edge) sensors and Close non-contact (photoelectric) sensors. In this

way a photoelectric sensor could be utilized to guard the gate area when

closing and an edge sensor would provide the protection when opening.

Depending on the particular application a combination contact and non-

contact sensor protection system for the open and close directions may

provide more effective entrapment protection than a single device for

both directions. See pages 4, 5, 11, 12, 13, 17, 19, 23, and 24.

SMART™ Self adjusting MAximum Run Timer

The RSX4000 has a

S

elf adjusting

MA

ximum

R

un

T

imer, SMART™.

The amount of time for the first few cycles of operation are registered

and averaged within the motor controller circuitry. After the first few

initial cycles, if the gate is activated and no other command is given or

an end limit (open or close) is not reached in the previously counted

cycle time plus approximately 4 seconds, the operator will be turned

off. See page 22.

OTHER FEATURES

Auto Close Timer:

Adjustable from 2 to 60 seconds, provides an

automatic closure of the gate from the full open position. See page 21.

Synchronous Operation (Master/Slave)

: Two RSX4000 units can be

wired together to operate as one system, with one unit controlling the

movement of both. Additionally, the installer can customize the

installation of the external entrapment protection devices. These

devices can be wired to the controller operator or alternately to the

individual units as the situation dictates or the end user requires. See

Page 16.

NOTICE

THE IMPORTANT SAFEGUARDS AND

INSTRUCTIONS IN THIS MANUAL CANNOT COVER ALL

POSSIBLE CONDITIONS AND SITUATIONS WHICH MAY

OCCUR DURING ITS USE. IT MUST BE UNDERSTOOD

THAT COMMON SENSE AND CAUTION MUST BE

EXERCISED BY THE PERSON(S) INSTALLING,

MAINTAINING AND OPERATING THE EQUIPMENT

DESCRIBED HEREIN. DO NOT USE THIS EQUIPMENT

FOR ANY OTHER THAN ITS INTENDED PURPOSE —

OPERATING A SWING GATE.

NOTICE

BEFORE ATTEMPTING INSTALLATION,

READ THIS MANUAL CAREFULLY SO YOU WILL

BE THOROUGHLY FAMILIAR WITH THE

FEATURES OF THE TWIST'R PLUS AND IT’S

PROPER INSTALLATION PROCEDURES.

PRE-INSTALLATION NOTES

3