LINCOLN GmbH • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259 • Tx 466088

Subject to modifications

Owner Manual

Technical Description

Page 11 from 13

2.1A-28001-A94

• Fault: Pump operates without discharging lubricant

• Cause

•

Remedy

• Lubricant reservoir is empty.

•

Check reservoir, refill, if necessary.

• Air pockets in lubricant.

•

Vent air from pump. See instructions „ Commis

sioning of the pump“. If applicable, renew lubricant.

• Fault: No compressed air on pump air cylinder

• Cause

•

Remedy

• 3/2-way valve defective

•

Check solenoid valve, repair or replace, if necessary.

• Fault: No compressed air available at air cylinder, piston does not complete its stroke (indicator pin does not move)

• Cause

•

Remedy

• Blockage in lubricant line.

•

Pressurize pump. Loosen pump body fittings and check for

lubricant discharge. then loosen fittings at metering devices

or lubrication points until lubricant emerges from outlets and

the pump begins to run. This will indicate in which line the

blockage has occured. After the blockage hasbeen cleared,

re-tighten all loose fittings.

• Fault: Air escapes from cylinder vent tube. The air cylinder is operating and the piston is at top of stroke.

• Cause

•

Remedy

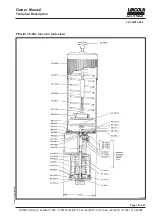

• O-ring 219-13043-6 or pneumatic piston 504-30342-1

•

Disconnect air supply. Unscrew bottom 314-18770-2. Remo-

worn or damaged.

ve piston and dissemble all parts. Replace O-ring 219-12451-

5, O-ring 219-13043-6, pneumatic piston with packing 504-

30342-1and retaining ring 211-12472-2 . Reassembly piston

assembly and lubricate lightly with oil. Loosen vent screw

counter nut and open vent screw approximately one turn

(DO NOT REMOVE)) and install piston assembly. Replace

O-ring 219-12225-6 and reassembly air cylinder bottom. Re-

connect air supply. Operate pump until lubricant flows from

vent screw, then tighten vent screw and counter nut.

• Fault: Lubricant discharged from vent tube.

• Cause

•

Remedy

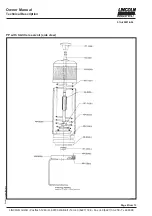

• O-ring 219-12451-5 worn or damaged

•

Disconnect air supply. Unscrew bottom 314-18770-2. Remo-

ve piston assembly and replace O-Ring 219-12451-5. Lightly

lubricate piston with oil. Loosen the counter nut at vent screw

and open vent screw approximately one turn (DO NOT RE-

MOVE) and install piston assembly. Replace O-ring 219-

12225-6 and reassembly air cylinder bottom. Reconnect air

supply. Operate pump until lubricant flows from vent screw,

then retighten vent screw and counter nut.

Troubleshooting