English

English

15

Loading the Electrode Wire

Turn the input power OFF.

Open the spool wire case.

Unscrew the locking nut of the sleeve.

Load the spooled wire on the sleeve such that the

spool turns clockwise when the wire is fed into the

wire feeder.

Make sure that the spindle brake pin [38] goes into

the fitting hole on the spool.

Screw in the locking nut of the sleeve.

Open the wire drive door.

Put on the wire roll using the correct groove

corresponding to the wire diameter.

Free the end of the wire and cut off the bent end

making sure it has no burr.

WARNING

Sharp end of the wire can hurt.

Rotate the wire spool clockwise and thread the end

of the wire into the wire feeder as far as the Euro

Socket.

Adjust force of pressure roll of the wire feeder

properly.

Adjustments of Brake Torque of Sleeve

To avoid spontaneous unrolling of the welding wire the

sleeve is fitted with a brake.

Adjustment is carried by rotation of its screw M10, which

is placed inside of the sleeve frame after unscrewing the

locking nut of the sleeve.

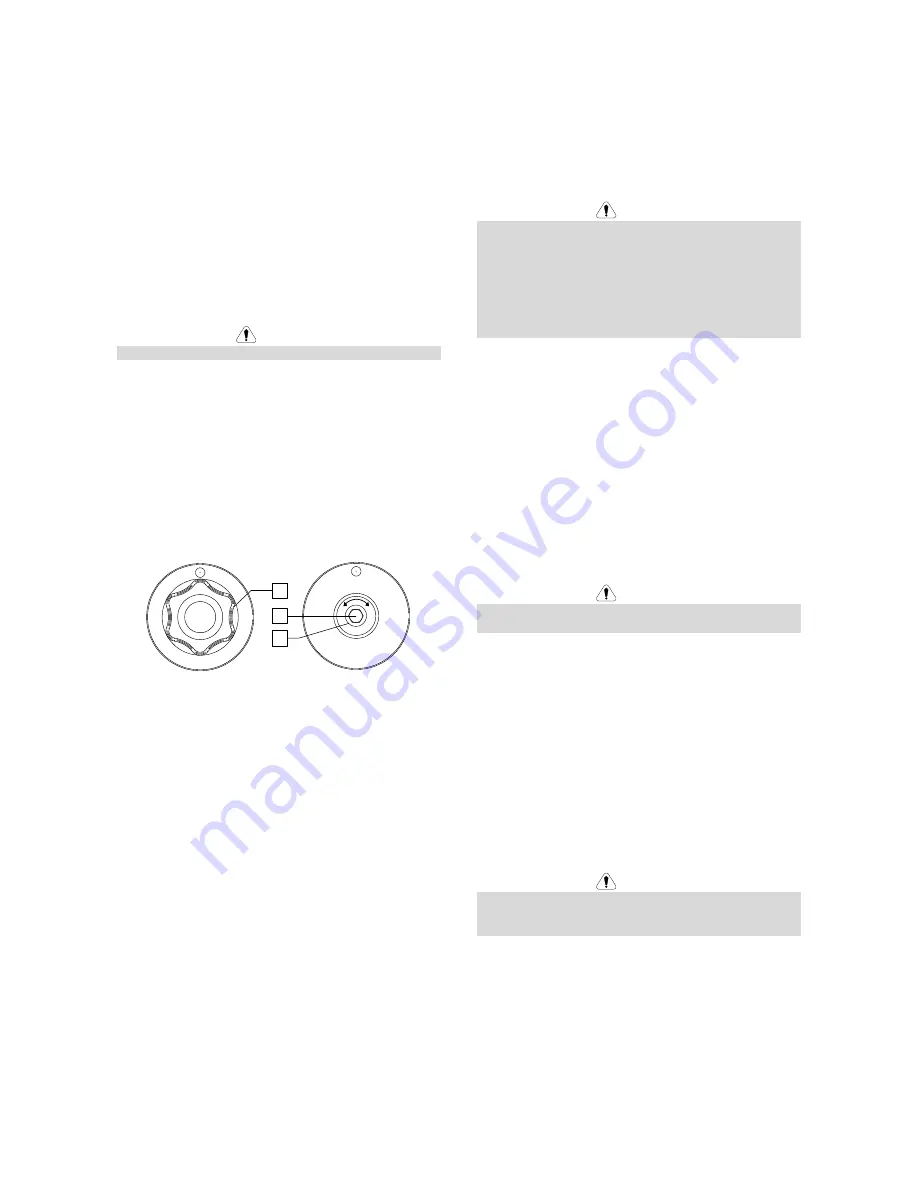

35

51

52

Figure 27.

35. Locking Nut.

51. Adjusting Screw M10.

52. Pressing Spring.

Turning the screw M10 clockwise increases the spring

tension and you can increase the brake torque

Turning the screw M10 anticlockwise decreases the

spring tension and you can decrease the brake torque.

After finishing of adjustment, you should screw in the

locking nut again.

Adjusting Pressure Roll Force

The pressure arm controls the amount of force the drive

rolls exert on the wire.

Pressure force is adjusted by turning the adjustment nut

clockwise to increase force, counterclockwise to

decrease force. Proper adjustment of pressure arm

gives the best welding performance.

WARNING

If the roll pressure is too low the roll will slide on the wire.

If the roll pressure is set too high the wire may be

deformed, which will cause feeding problems in the

welding gun. The pressure force should be set properly.

Decrease the pressure force slowly until the wire just

begins to slide on the drive roll and then increase the

force slightly by turning of the adjustment nut by one

turn.

Inserting Electrode Wire into Welding

Gun

Turn the input power OFF.

Depending on welding process, connect the proper

gun to the Euro Socket, the rated parameters of the

gun and of the welding machine should be matched.

Remote the nozzle from the gun and contact tip or

protection cap and contact tip. Next, straighten the

gun out flat.

Insert the wire through the guide tube, over the roller

and through the guide tube of Euro Socket into liner

of gun. The wire can be pushed into the liner

manually for a few centimetres, and should feed

easily and without any force.

WARNING

If force is required it is likely that the wire has missed the

liner of gun.

Turn the input power ON.

Depress the gun trigger to feed the wire through the

gun liner until the wire comes out of the threaded

end. Or the Cold Inch / Gas Purge Switch [12] can be

used – keep in "Cold Inch" position until the wire

comes out of the threaded end.

When trigger or the Cold Inch / Gas Purge Switch

[13] is released spool of wire should not unwind.

Adjust wire spool brake accordingly.

Turn the welding machine off.

Install a proper contact tip.

Depending on the welding process and the type of

the gun, install the nozzle (GMAW process, FCAW-

GS process) or protection cap (FCAW-SS process).

WARNING

Take precaution to keep eyes and hands away from the

end of the gun while the wire is being come out of the

threated end.

Summary of Contents for PF41

Page 23: ...English English 20 Connection Diagram ...

Page 24: ...English English 21 ...

Page 25: ...English English 22 ...