- 15 -

Operation & Maintenance Manual

User setting consists of 2 screens. Movement can be done with clicking arrow

▽

,

△

Through user

setting, operator can make up the control parameter of chiller.

Operator basically can check and change the control setting condition of cold water outlet tempera-

ture. Among temperature setting items, target temperature of cold water outlet temperature and con-

trol range can be set by operator in user setting screen. Also by setting preheat function, operator

can set machine to operate only after ranged preheat time when power is ON.

For changing value, select the part which indicates the value and select the number which operator

wants to change to. If operator wants to cancel the change, select CLR, it would be cancelled. Stop

and Re-start temperature would be set automatically by setting Stop temperature Dt, Re-start Dt in

parameter setting. Stop temperature means the temperature at which compressor would be

stopped. Setting condition is 5.0ʼC. Re-start temperature means the temperature in case that com-

pressor should be re-started after Stop. Setting condition is 9.0ʼC. Difference of Stop temperature

and Re-start temperature prevent often re-start of compressor.

Oil preheat can be set as Use/Nonuse, by minute unit. In the region where outdoor temperature is

low, oil needs to be preheated to ensure proper thickness of oil.

Control mode consists of Local Control/Tele Control, Hand Control/Auto control and MODBUS

Use/Nonuse. In case of Local Control, chiller may be operated by key controlling of operator. If

mode is changed to tele control, Start and Stop of chiller may be done by the condition of tele con-

tact part.

In case of Auto control, chiller would Start and Stop automatically by operator setting operation

schedule. Schedule setting can be done in function setting menu. Contrarily, in case of Hand

Control, chiller would be operated by key control of operator or tele signals.

MODBUS would be used to conduct the control after connecting chiller to BMS and MODBUS

through network.

Operator can change password in second screen. Some function of HMI would be protected by

password. Password change can be done by selecting New Password , re-input it and complete it

by clicking OK.

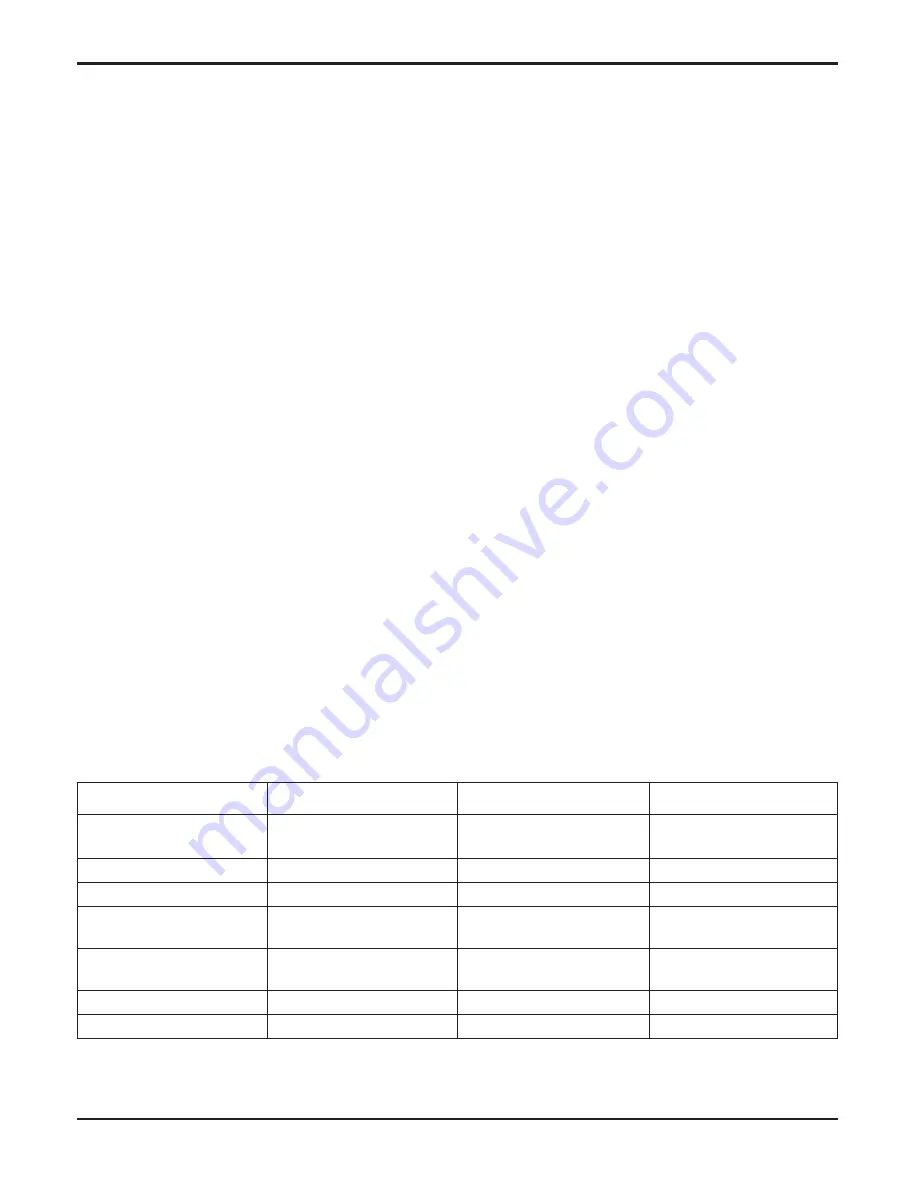

Setting range of user setting value is specified below.

Table 1

Indication

Target Temp

Control Range

Preheat Function

Local Control/

Tele Control

Hand Control/

Auto Control

MODBUS

Code

Meaning

Setting temperature

of cold water outlet

Control Range

Preheat function

Local Control/

Tele control

Hand Control/

Auto Control

MODBUS Use

User input Password

Setting Range

5°C~12°C

0.6°C~1.5°C

Use/Nonuse

Local Control/

Tele Control

Hand Control/

Auto Control

Use/NonUse

XXXX

Basics

7°C

0.6°C

Use

Local Control

Hand Control

NonUse

6666