- 69 -

Operation & Maintenance Manual

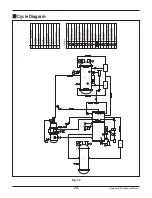

The two causes of anti-freeze switch are as follows. Actually the alarm is recognized by the anti-

freeze switch of low water temperature detected by the temperature sensor. For low water tempera-

ture, the alarm setting temperature can be changed by the HMI.

In case of any mechanically welded contactor problem of the magnetic contactor of the compressor,

PLC cannot stop the compressor. Due to this reason, the alarm will not be generated in this case.

Therefore, in this case, the circuit breaker in front of the magnet contactor with the error must be

turned OFF.

Discharge temperature issue occurs when the compressor discharge temperature is 80°… or above.

This occurs when the refrigerant is insufficient or the coolant water outlet temperature is too high.

COMM error issue means the communication error between HMI device and PLC and the loose

connection is identified as the frequent cause.

•

•

•

•

• Repair or replace controller

• Charge refrigerant

• Overcharge refrigerant

• High pressure switch error

• Air mixed to refrigerant

•

• Controller DI point error

• Insufficient refrigerant

• High pressure switch trip

Pressure alarm

•

•

• Cold water pipe valve open

•

• Cold pump error

• Insufficient cold water

•

•

•

Flow alarm

• Check power

•

• Over-voltage

• Under-voltage

• Reverse phase

• Voltage imbalance

• Missing phase

•

5E alarm

•

•

•

2

)

Dp alarm

•

• Emergency switch trip

•

Emergency stop

Potential solution

Potential cause

Recognition

Displayed alarm

message

Turn the emergency switch in

clockwise direction

Review cold water

temperature sensor

Repair or replace 5E

protective switch

Repair or replace cold water

pump

Purse air and supplement

water

Change flow switch operation

setting value or replace

device

Remove overcharged

refrigerant

Repair or replace high

pressure switch

After removing refrigerant,

execute vacuum work and

recharge

Increase high pressure

switch setting

High pressure switch

setting is too low

flow switch setting or

error in device itself

Cold water pipe valve

closed

Cold water temperature

too high

Emergency switch input

(Switch off)

After compressor

operation differential,

pressure switch trip

(Switch off)

(Basic: DP<4kgf/cm

Voltage monitoring relay

trip (Switch off)

After cold water pump,

cool water switch

(Switch off)