- 47 -

Operation & Maintenance Manual

Main function of the lubrication oil within the screw compressor is to lubricate, seal internally, cool and control

the capacity. Hydraulic pressure within the cylinder moves the piston connected to the piston road and the slide

valve back and forth. The design of screw compressor includes the lubrication system by the differential pres-

sure between the high and low pressure, and does not require separate installation of additional oil pump within

the compressor. But for some special equipment, additional installation of the oil pump is required for safety

purposes.

Bearing used in the compressor requires small but a certain amount of lubrication oil and the reason for insert-

ing the oil into the compressor compartment is to increase the efficiency and to create an oil seal within the

compression housing to absorb the compression heat. To separate the oil from the refrigerant with the oil

mixed, the oil separator is designed to let minimum amount of oil get into the system. Special care is needed for

the temperature, which is the significant element in the life of the compressor bearing. High oil temperature

reduces the viscosity and deteriorates the lubrication within the compressor and the heat absorption condition.

It is recommended to maintain the oil viscosity at 10mm

2

/s or above at any temperature range. Oil temperature

must be maintained to system condensation temperature or above to avoid the mixed refrigerant from penetrat-

ing into the system during summer. Oil viscosity must be high and the compressor must have high durability

when the external temperature is low to reduce the hydraulic pressure within the oil pipe to load the compres-

sor. A better solution is to preheat the oil to create higher condensation temperature in a short period of time.

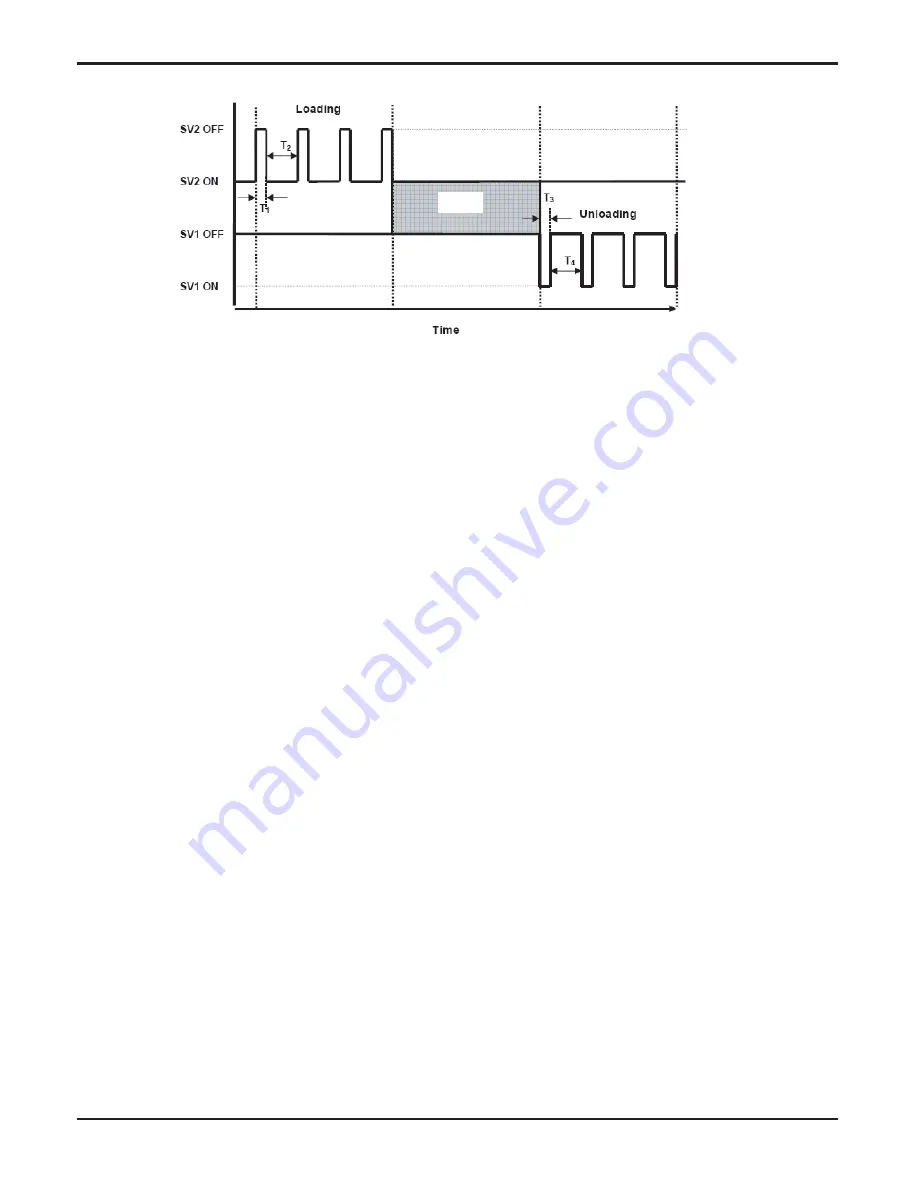

Stable

ON : Solenoid valve energized

OFF : Solenoid valve not energized

T1, T3 : Pulse time 0.5 ~ 1.5 seconds

T2, T4 : Pause time 10 ~ 20 seconds

Fig. 20