2

SAFETY INSTRUCTIONS

ENGLISH

WARNING

• Installation or repairs made by unqualified persons can result in

hazards to you and others.

• The information contained in the manual is intended for use by a

qualified service technician familiar with safety procedures and

equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual

can result in equipment malfunction, property damage, personal

injury and/or death.

Installation

• For installation of the product, always contact the service center or

a professional installation agency.

- Otherwise, it may cause fire, electrical shock, explosion or injury.

!

WARNING

This indicates that the failure to follow the instructions can

cause serious injury or death.

CAUTION

This indicates that the failure to follow the instructions can

cause the minor injury or damage to the product.

This symbol is displayed to indicate matters and operations

that can cause risk.

Read the part with this symbol carefully and follow the

instructions in order to avoid risk.

!

!

!

SAFETY INSTRUCTIONS

The following safety guidelines are intended to prevent unforeseen

risks or damage from unsafe or incorrect operation of the appliance.

The guidelines are separated into ‘WARNING’ and ‘CAUTION’ as

described below.

Summary of Contents for PAHCMR000

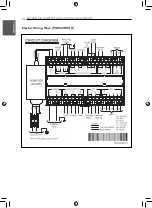

Page 14: ...14 RETURN AIR TEMPERATURE CONTROL PAHCMR000 ENGLISH Electric Wiring Work PAHCMR000 ...

Page 46: ...46 ENGLISH ...

Page 47: ......