38

MultiSITE CRC 2 Controller

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

ACCESSORIES INSTALLATION

CO

2

, Temperature, and Humidity Sensor

SEDCO2G5045 / Temperature and Humidity Sensor

ZVRCZTRH1

Follow this procedure to install the optional SEDCO2G5045 and ZVRCZTRH1

sensors.

Consider the following location constraints before installing a ceiling/wall sensor:

•

Do not install a on metal surface.

•

Do not install in areas with a direct heat source.

•

Do not install near any air discharge grill.

•

Do not install in areas exposed to direct sunlight.

•

Ensure mounting surface is flat and clean.

• Install in a dry location away from water, moisture, or rain.

Sensor Installation

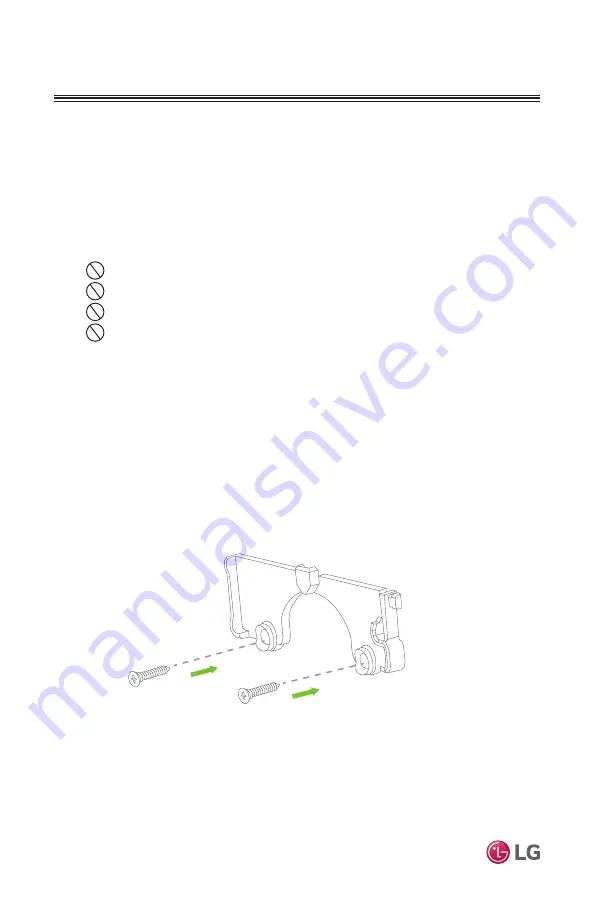

The wireless CO2 + TRH / TRH sensors can be secured directly on a wall or flat

surface using double-sided adhesive tape or by securing the plastic bracket to the

wall and mounting the sensor. Using the screws is the recommended method.

1. Using two screws provided, secure wall bracket to wall (Figure 41).

2. Once bracket is secured, slide sensor on bracket using downward motion.

Figure 41: Wall Bracket Installation

Summary of Contents for MultiSITE CRC2 Series

Page 49: ......